Have you ever wondered just how much it really costs to run a CNC machine? As a precision manufacturer, I get this question all the time from customers considering CNC machining for their parts. The hourly rate can vary widely depending on factors like the machine type, specifications, operational costs, programming requirements, and part quantities.

In this post, I’ll break down the key elements that determine a CNC machine’s hourly cost such as equipment purchase options, ongoing maintenance fees, labor expenses, and economies of scale. We’ll also look at strategies for optimizing your machine’s value over its lifespan. Whether you’re budgeting a one-off job or long-term production run, understanding these cost components can help you estimate CNC pricing and make informed decisions for your application.

By the end, you’ll have a clear picture of how equipment choices, part design, and production volumes all play a role in hourly rates. So read on to learn how I assess cost factors and what you can do to maximize efficiency from your investment in CNC machining technology.

1. Factors that affect hourly CNC machine rates

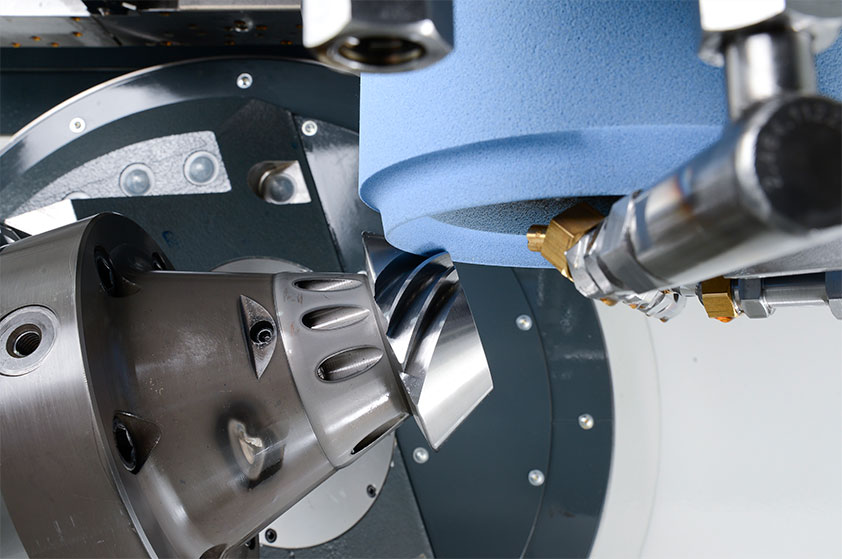

There are several key factors that influence the hourly rate to run a CNC machine. The most significant is the machine type – mills, lathes, routers, and other specialized machines have very different specifications and capabilities that are reflected in their price. Additional considerations include the machine’s maximum travel distances and spindle speeds, as well as the controls, drives, and any integrated automation. In general, more advanced machines capable of tighter tolerances and complex parts will demand a higher hourly rate.

2. Cost comparison of different CNC machine types (milling, lathe, etc.)

Milling machines are very flexible but generally have higher hourly rates than lathes. This is because mills can cut in multiple planes and axes, but require more complex programming and tooling. Lathes excel at rotational parts but are limited to single-axis cuts, keeping their hourly costs lower. Meanwhile, specialized routers or other niche machines may have premium rates reflecting their capabilities for complex 3D surfaces or unique materials. Comparing common machine types can give you a baseline for budgeting various CNC processes.

3. Upfront equipment purchase or rental costs

Whether you buy or rent CNC equipment has a significant effect on hourly rates. Purchasing involves large upfront capital, but spreads equipment and financing costs over thousands of hours of use. Renting eliminates large purchases but has much higher hourly rates to recoup costs. For short-run jobs or infrequent needs, renting may be more affordable, while purchase is preferable for high-volume production. The purchase price also depends greatly on the machine’s size, power, and features.

4. Operational costs like materials, tooling, power usage

Every hour of operation incurs costs for tooling replacement or sharpening, workholding devices, cutting fluids, and raw materials like stock removal alloys. Power consumption to run the spindle and other components also contributes to operational expenses. More advanced machines and materials may require specialized (and more expensive) tooling. Tracking usage helps estimate these variable costs per hour of run time. Proper maintenance is also crucial to maximize a machine’s efficiency and lifespan.

5. Maintenance and repair costs

All machines require regular maintenance to optimize performance over time. This may include scheduled lubrication, adjustments, or replacement of wear parts. Unplanned repairs for mechanical or electrical failures also factor into the total cost of ownership that affects hourly rates. More robust builds command higher prices but may have lower long-term repair expenses. Budgeting for preventative maintenance and maintaining service contracts can help control these unpredictable costs.

6. Impact of machine specifications on hourly rates

Attributes like the spindle speed, rapid traverse rates, and maximum part size affect process times and complexity of programming. Larger machines with higher precision specifications generally demand higher hourly rates. Similarly, machines with more advanced features like integrated rotary axes, automated tool changers, or multi-pallet loaders are more productive but have higher costs of operation. Understanding a machine’s technical capabilities is key to matching it to your part requirements cost-effectively.

7. Labor costs for CNC programming and operation

The time spent programming and setting up a CNC job, as well as operating it, represent labor expenses that factor into hourly rates. Complex geometries or tight tolerances may require more programming skill and validation time. Factoring in an operator’s wages and benefits gives you a fully loaded machine rate. Automation can reduce labor but requires larger capital investments. Outsourcing programming to specialists can keep costs lower for infrequent jobs. Efficient processes optimize labor productivity over the long run.

8. Economies of scale – how part quantity affects per-hour costs

Fixed costs like equipment purchases or programming time are amortized over the total number of parts produced. Therefore, larger production volumes achieve significant economies of scale that drive down the per-part and per-hour costs. One-off jobs or short runs involve high setup fees but low per-hour rates once running. Calculating your break-even volume is important to understand minimum order quantities needed to make CNC manufacturing cost-effective versus alternatives like production machining.

9. Amortizing large capital expenses over expected machine lifespan

The number of annual operating hours used to calculate depreciation expense from a machine purchase has a major impact on hourly rates. A $500,000 machine that runs for 5,000 hours per year will be less expensive per hour than one running at 2,500 hours. Budgeting machine downtime for maintenance is also important to maximize uptime. With proper care, machine life expectancies of 15-20 years are common. Careful planning ensures large investments are fully leveraged over the long term.

10. Strategies for getting the most value from your CNC machine time

Maximizing tool life, optimizing code, and reducing non-cutting motions saves significant time and money per part. Attention to fixturing and clamping avoids scrapped components from loss of position. Machine simulations can catch errors early. Well-organized jobs minimize setup and changeover times. Outsourcing non-core work or overflow avoids underutilizing an expensive capital asset. Regular training keeps operators sharp. With diligent process planning, it’s possible to cut hourly rates by 25% or more over time.

Post time: Jan-29-2024