Products

CNC Machining in Aluminum

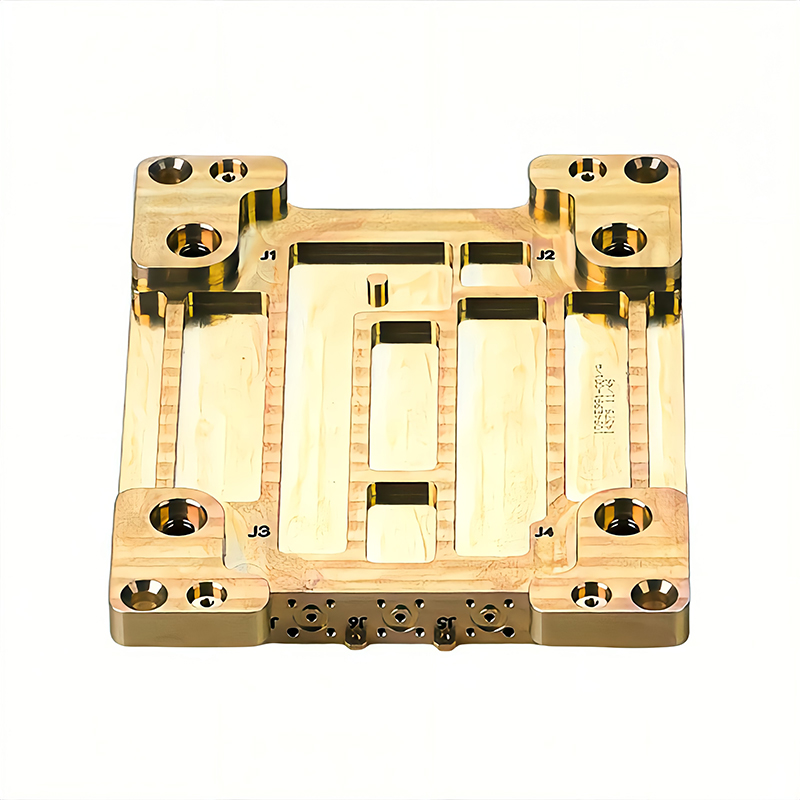

CNC Machining in Copper

Copper has excellent thermal and electrical conductivity, making it ideal for electrical wiring, printed circuit boards, and heat exchangers. It is also highly ductile and malleable, allowing for easy shaping and forming. Copper alloys have good corrosion resistance and antimicrobial properties, making them suitable for medical and food processing applications.

Copper materials are commonly used in CNC machining processes.

CNC machining is a manufacturing method for producing parts with exceptional mechanical properties, as well as high precision and repeatability. This process can be applied to both metal and plastic materials. In addition, CNC milling can be performed using 3-axis or 5-axis machines, providing flexibility and versatility in the production of high quality parts.

Application

CNC machining is commonly used to produce high-quality parts made of metal and plastic, offering outstanding mechanical properties, precision, and consistency. It is capable of both 3-axis and 5-axis milling.

Strengths

CNC machining stands out for its exceptional mechanical properties, delivering parts with superior strength and durability. Additionally, it offers high accuracy and repeatability, ensuring consistent results.

Weaknesses

Compared to 3D printing, CNC machining has more limitations in terms of the complexity of geometries that can be produced.

Price

$$$$$

Lead Time

< 10 days

Tolerances

±0.125mm (±0.005″)

Max part size

200 x 80 x 100 cm

To CNC mill copper, you can follow these steps:

Prepare your CAD files: Create or obtain a 3D model of your desired copper part in CAD software, and save it in a compatible file format (such as . STL).

Select appropriate cutting tools: Choose the appropriate cutting tools for milling copper. Carbide end mills are commonly used for copper machining due to their high hardness and heat resistance.

Set up the CNC machine: Install the selected cutting tools and secure the copper workpiece onto the CNC machine's work table. Ensure proper alignment and clamping to prevent any movement during the milling process.

Program the CNC machine: Use CAM software to generate the toolpaths and instructions for the CNC machine. Specify the cutting speeds, feeds, and depths for milling copper.

Run the CNC milling process: Start the CNC machine and let it execute the programmed instructions. The cutting tools will remove material from the copper workpiece according to the specified toolpaths, gradually shaping it into the desired form.

Finishing and post-processing: Once the milling process is complete, remove the copper part from the CNC machine. Perform any necessary post-processing steps, such as deburring or polishing, to achieve the desired surface finish.

By following these steps, you can CNC mill copper and create precise and intricate parts according to your design.

The cost of CNC machining copper can vary depending on factors such as the complexity and size of the part, the type of copper, and the quantity of parts needed. These variables affect the machine time required and the cost of raw materials. To get an accurate cost estimate, you can upload your CAD files onto our platform and use the quote builder to receive a customized quote. This quote will consider the specific details of your project and provide you with the estimated cost of CNC machining your copper parts.