Products

CNC machining materials

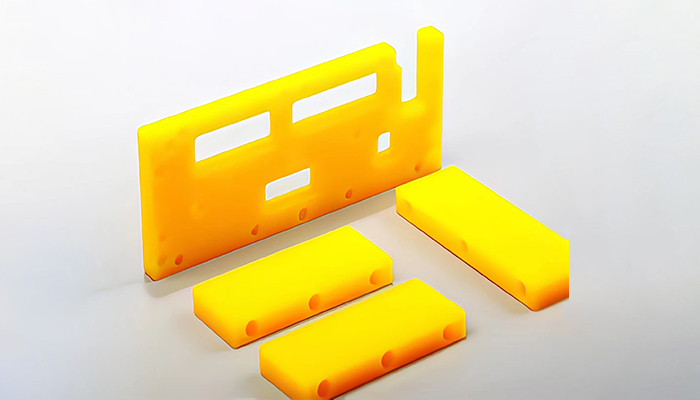

CNC Machining in PU

Plastics are another common material used in CNC turning because they are available in many different options, are relatively inexpensive, and have faster machining times. Commonly used plastics include ABS, acrylic, polycarbonate and nylon.

PU (Polyurethane) Description

PU is a versatile elastomeric material known for its flexibility, durability, and chemical resistance. It is often used in applications that require cushioning, insulation, and impact resistance.

Application

Foam cushions and mattresses

Seals and gaskets

Coatings and adhesives

Automotive components

Strengths

Flexibility and elasticity

Excellent cushioning and impact resistance

Chemical resistance

Good abrasion resistance

Weaknesses

Limited heat resistance

Can be prone to degradation under UV exposure

Price

$$$$$

Lead Time

< 2days

Wall Thickness

0.8 mm

Tolerances

±0.5% with a lower limit of ±0.5 mm (±0.020″)

Max part size

50 x 50 x 50 cm

Layer height

200 - 100 microns

Popular science information about PU

PU (Polyurethane) is a versatile and highly adaptable polymer that is widely used in various industries. It is formed through the reaction of diisocyanates with polyols, resulting in a wide range of polyurethane materials with different properties and applications.

PU is known for its excellent abrasion resistance. It can withstand repeated friction and wear, making it suitable for applications that require durability, such as in industrial machinery components, conveyor belts, and coatings for floors and surfaces.

PU is a lightweight material, which makes it suitable for applications where weight reduction is desired. It has a low density compared to other materials, such as metals and glass, while still providing comparable strength and performance. This property makes PU a popular choice for applications that require both strength and lightweight characteristics, such as in aerospace components and sports equipment.

PU is also known for its excellent thermal insulation properties. It has a low thermal conductivity, making it an effective insulator against heat and cold. This property makes PU suitable for applications that require thermal insulation, such as in building insulation, refrigeration, and thermal packaging.