Codsiga

alaabta biraha ah ee wax soo saarka beerta

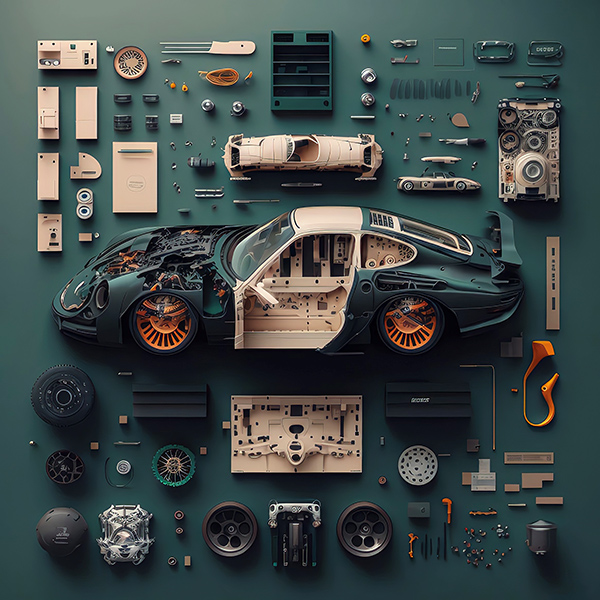

───── Walxaha caadiga ah ee birta ah iyo codsiyadooda ku jira soo saarista baabuurta ─────

Bandhiga Agabka Birta

1. Daawaha aluminium: Alloynka aluminiumku wuxuu leeyahay miisaan fudud, wuxuu leeyahay awood sare iyo iska caabin wanaagsan oo daxalka ah waxaana inta badan loo isticmaalaa soo saarista jirka baabuurta iyo qaybaha dhismaha.Tusaale ahaan, qolofka jirka, albaabada, daboolka, iyo qaybaha chassis-ka ayaa inta badan laga sameeyaa daawaha aluminium si loo yareeyo culeyska baabuurka loona hagaajiyo waxtarka shidaalka.

2. Birta aan lahayn: birtu waxay leedahay iska caabin daxalka, xoog sare, iyo iska caabin heerkul sare ah, oo caadi ahaan loo isticmaalo soo saarista hababka qiiqa baabuurta, hababka qaadashada hawada, iyo hababka hawo-mareenka.Tusaale ahaan, qaybaha sida tuubooyinka qiiqa, tuubooyinka hawada qaada, tuubooyinka hawo-qaadista, iyo dareemayaasha ayaa inta badan laga sameeyaa birta aan fiicnayn si loo hagaajiyo adkeysiga iyo isku halaynta.

───── Walxaha birta ah iyo codsiyadooda soo saarista robot-ka ─────

Bandhiga Agabka Birta

1. Copper Alloys: Copper Alloys waxay leeyihiin koronto iyo kulayl wanaagsan waxaana inta badan loo isticmaalaa soo saarista hababka korantada iyo hababka kulaylka ee robots.Tusaale ahaan, qaybaha aaladaha sida fiilooyinka, fiilooyinka, weelasha kulaylka, iyo xiriiriyeyaasha baytariga ayaa inta badan lagu soo saaraa iyadoo la isticmaalayo alaabo naxaas ah si ay u bixiyaan kuleyl wanaagsan oo korantada ah.

2. Daawaha aluminium: Alloynka aluminiumku waa mid ka mid ah biraha caadiga ah ee loo isticmaalo wax soo saarka robot, kaas oo leh miisaan fudud, xoog sare, iyo iska caabin wanaagsan.Jidhka, qaabka, iyo qaybaha qaab dhismeedka robots-yada waxaa inta badan laga soo saaraa aluminium aluminium si loo yareeyo miisaanka guud loona hagaajiyo dhaqdhaqaaqa iyo dabacsanaanta robotka.

───── Walxaha macdanaha ah ee caadiga ah iyo codsiyadooda soo saarista diyaaradaha aan duuliyaha lahayn ─────

Bandhiga Agabka Birta

1. Birta aan lahayn: Birta birta ah waxay leedahay iska caabin daxalka, xoog sare, iyo iska caabin heerkul sare ah, waxaana caadi ahaan loo isticmaalaa soo saarista dareemayaasha, qalabka elektaroonigga ah iyo nidaamyada hawada ee UAVs.Tusaale ahaan, guryaha dareemayaasha ee UAV, qalabka elektarooniga ah ee xirmooyinka fiilooyinka, iyo qaybaha kale ayaa badanaa la soo saaraa iyadoo la isticmaalayo birta aan fiicnayn si loo bixiyo ilaalin wanaagsan iyo isku halaynta.

2. Magnesium alloy: Magnesium alloy waxay leedahay miisaan fudud, xoog badan, iyo sifooyin farsamo oo wanaagsan, waxayna ku habboon tahay samaynta UAV-yada fudud.Tusaale ahaan, baalasha, qolofka qolofka, iyo qaybaha dhismaha ee UAV waxaa badanaa lagu soo saaraa iyadoo la isticmaalayo daawaynta magnesium si loo yareeyo miisaanka guud oo loo hagaajiyo wakhtiga duulimaadka iyo awoodda culeyska.

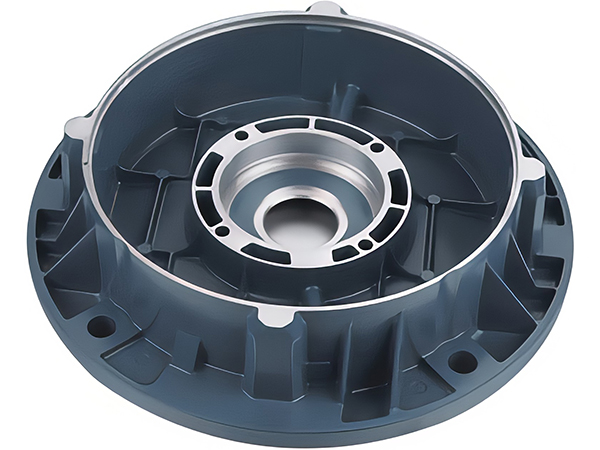

───── Walxaha birta ah iyo codsiyadooda ku aaddan goobta saliidda laga soo saaro ─────

Bandhiga Agabka Birta

1.Aluminium Alloy: Aluminium aluminiumku wuxuu leeyahay miisaan fudud, xoog sare iyo heerkulka wanaagsan ee kuleylka waxaana badanaa loo isticmaalaa soo saarista qaybaha qaabdhismeedka iyo radiators qalabka soo saarista saliidda.Tusaale ahaan, dhufto ee ka sameysan aluminium aluminium ah ayaa loo isticmaalaa in lagu taageero oo lagu hagaajiyo qalabka, iyo hiitarka aluminium aluminium ayaa loo isticmaalaa in lagu baabiiyo kulaylka iyo qaboojinta.

2.Titanium Alloy: Iyada oo leh awood sare, cufnaanta hoose iyo iska caabbinta daxalka wanaagsan, Alloys titanium ayaa inta badan loo isticmaalaa soo saarista qaybaha daxalka u adkaysta iyo qaybaha heerkulka sare ee qalabka soo saarista saliidda.Tusaale ahaan, alwaaxyada alwaaxyada titanium waxaa loo isticmaalaa in lagu xakameeyo heerkulka sare iyo dareeraha cadaadiska sare, iyo boolalka titanium alloy waxaa loo isticmaalaa in lagu xiro qalabka muhiimka ah.

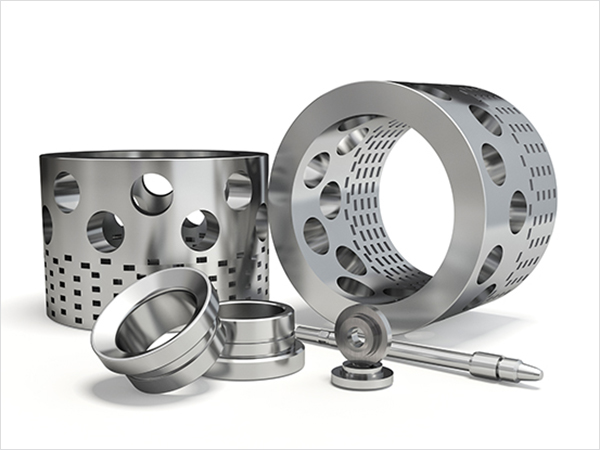

Adeegyada CNC Birta

Khibrad u yeelo adeegyada goynta birta ee ugu sarreeya ee CNC ee Kachi, oo bixiya waqtiyo tayo leh oo aan laga adkaan karin.waxaanu awood noo siinaynaa inaanu fulino amarada mugga yar ee qaybaha birta ee CNC iyo wax ka qabashada mashaariicda farsamaynta adag.Haddii aad u baahan tahay prototypes ama wax-soo-saarka mugga hoose, awoodahayada CNC ee farsamaynta biraha waxay dabooshaa biro kala duwan iyo dhamaystirka dusha sare.Nala wadaag maanta si aad u taabato silsilada sahayda biraha ee CNC ee baladhan.

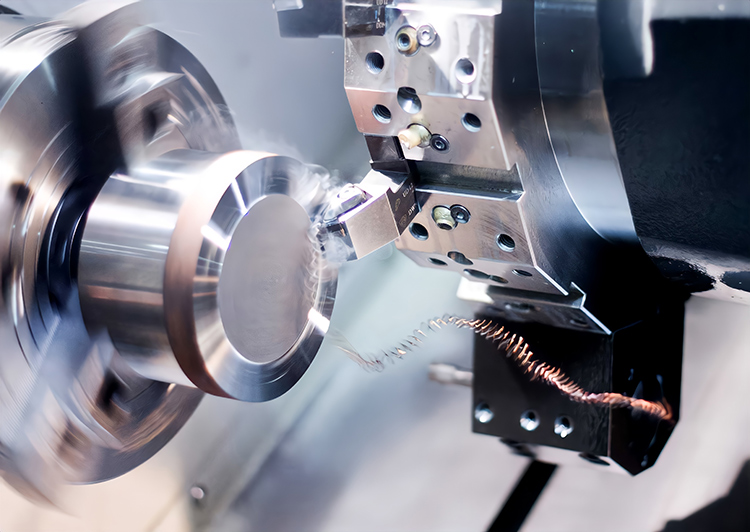

Mashiinka Birta

Mashiinka birta waxay ku lug leedahay in si sax ah loo gooyo birta ceyriinka ah si loo gaaro qaabka ama shayga la rabo.Mashiinnada CNC (Kontoroolka Tirooyinka Kombuyuutarada), oo ay wataan CAD (Computer Aid Design Design) software, waxay bixiyaan saxnaanta aan la barbar dhigi karin ee soo saarista walxaha saddex-geesoodka ah.Shabakaddayada mashiinada xirfadda leh waxay inta badan adeegsataa mashiinnada 3- iyo 5- dhidibka CNC ee horumarsan kuwaas oo si sax ah u jari kara sifooyinka adag iyadoo la hubinayo dulqaad adag.Waxa kale oo aanu samaynaa online DFM (Naqshadda wax soo saarka) hubinta si loo ilaaliyo heerarka tayada sare.

CNC Metal Fabrication

Wax-soo-saarka birta ee CNC waa hab ku habboon in birta loo qaabeeyo qaabab qallafsan, oo la mid ah in la xardho sabuurad alwaax ah laakiin leh saxnaanta birta, laylisyada, iyo kumbuyuutarrada.Isticmaalka mashiinnada CNC, waxaan ka samaysan karnaa qaybaha birta ee hal shay, taasoo keentay wax soo saar hufan oo sax ah.

Shaxda Isbarbardhigga Agabka

| Biraha | USA | Japan | Jarmalka |

| Bir daxal laheyn | 303 | SUS303 | Y1Cr18Ni1.4305 |

| 304 | SuS304 | X5CrNi1891.4301 | |

| 316L | SUS316L | X2CrNiMo1812 | |

| 316 | SUS316L | 1.4436 | |

| 202 | SU316 | X12CrNi177 | |

| 410 | SuS202 | x1oCr13 | |

| 416 | SuS410 | X12CrS13 | |

| - | SUS416 | 1.4021 | |

| 440C | SUS420 | W.1.4125 | |

| 430 | SUS440C | x8Cr17 | |

| 17-7PH | SuS430 | 1.4568 (1.4504) |

| Biraha | USA | Japan | Jarmalka |

| Birta Kaarboonka | - | SAPH38 | St37-2 |

| 1020 | S20C | CK20 | |

| 1045 | S45C | CK45 | |

| 1213 | SUM22 | 9SMn28 |

| Biraha | USA | Japan | Jarmalka |

| Goynta Birta | 12L14 | SUM24L | 9SMnpB28 |

| Biraha | USA | Japan | Jarmalka |

| Alloy Steel | 4140 | SCM440 | 42CrMo4 |

| P20 | PDS-3 | 1.2311 | |

| D2 | X210Cr12 | SKD11 |

| Biraha | USA | Japan | Jarmalka |

| Bronze | C54400 | C5441 | - |

| C51900 | C5191 | CuSn6 | |

| C17200 | C1720 | CuBe2 |

| Biraha | USA | Japan | Jarmalka |

| Aluminium | 6061 | A6061 | AlMg1SiCu |

| 5052 | A5052 | AlMg2.5 | |

| 5083 | A5083 | AlMg4.5Mn | |

| 7075 | A7075 | AlZnMgCu1.5 | |

| 7175 | 7075 | AlZnMgCu1.5 | |

| 2024 | A2024 | AICuMg2 | |

| 2017 | A2017 | AlCu2.5Mg0.5 |

| Biraha | USA | Japan | Jarmalka |

| Copper | Т2 (99.90) | C1100 | E-Cu57 |

| C21000 | C2100 | CuZn5 | |

| C22000 | C2200 | CuZn10 | |

| C24000 | C2400 | CuZn20 | |

| C26000 | C2600 | Cuzn30 |

| Biraha | USA | Japan | Jarmalka |

| Alloys | 1045 | S45C | C45 |

| C.D | SS400 | S235JR | |

| 1050 | S50C | C50 |