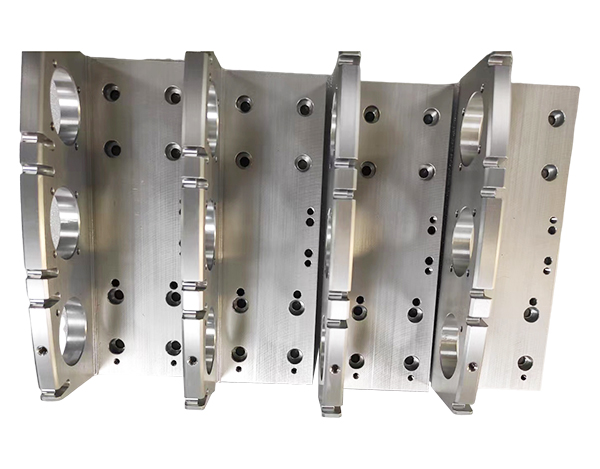

Dusha sare waxay u dhammaatay Mashiinka CNC

Dhamaystirka dusha sare waa hab ka caawiya qeexida iyo nadiifinta guud ahaan texture ka dib mashiinka CNC.

Kachi, waxaanu nahay kuwo tayo leh oo diyaar u ah inaanu u habaynno qaybaha isticmaalka kala duwan.Haddii aad u hoggaansan tahay dulqaadka cabbirka adag iyo dhammaystirka siman ama aad u baahan tahay daxal dheeri ah oo aad xidhato iska caabin, dhammaystirkayada dusha sare ee mashiinka CNC ayaa soo saari kara waxaad u baahan tahay.

Waa maxay Dhammaadka Dusha Mashiinka?

Dhamaystirka dusha sare waxa ay ku lug leedahay habka wax ka beddelka biraha birta iyada oo dib-u-qaabayn, ka saarid ama isku-dar, waxaana loo isticmaalaa in lagu cabbiro guud ahaan qaab-dhismeedka dusha oo lagu garto:

Jiif- Jihada qaabka dusha sare ee ugu sarreeya (badanaa waxaa lagu go'aamiyaa habka wax soo saarka).

Wanaag- Waxay khusaysaa cilladaha tafaasiisha wanaagsan ama khaladaadyada aadka u daran, sida sagxadaha rogman ama ka leexday tilmaamaha.

Dusha sare ee Roughness- Cabbir cilladaha dusha sare ee si yar u kala fogaaday.Guud ahaan, qallafsanaanta dusha sare waa waxa mashiinnadu u tixraacaan "dhamaadka dusha sare" halka isticmaalka "text texture" uu yahay mid caadi ah marka la eego dhammaan saddexda sifo.

Waa maxay noocyada qodobbada ay tahay in la tixgeliyo marka la dooranayo dhamaystirka dusha sare ee mashiinka CNC?

Codsiyada alaabta

Qodobbada deegaanka ee kala duwan, sida gariirka, kulaylka, qoyaanka, shucaaca UV, iwm, ayaa lagu dabaqaa qaybo kala duwan oo CNC ah.Waxaad dooran kartaa si xikmad leh haddii aad si taxadar leh uga fiirsato cidda iyo waxa alaabta loogu talagalay.

Waarta

Intee in le'eg ayaa aad rabto in badeecadaada ay jirto waa su'aal ay tahay in aad is weydiiso.Wax-soo-saarku waxay ku lug leedahay adkeysi badan.Qalabka cayriin ayaa muhiim u ah kiiskan, laakiin waa inaad sidoo kale tixgelisaa nadiifinta dusha sare ee mashiinka.Adkeysiga waa qodob kor u qaadaya qiimaha alaabtaada dhammaatay.Sidaa darteed, waa inaad doorataa dhammaadka ku habboon.

Cabirka qaybta

Waa muhiim in la xasuusto in dhamaystirka makiinadu uu bedeli karo cabbirka qayb.Dhammaadka dhumucda sida daahan budada ah waxay kordhin kartaa dhumucda dusha walaxda birta ah.

Faa'iidada Habka Dhamaystirka Dusha Sare ee Birta

Hawlaha daaweynta dusha birta waxaa lagu soo koobi karaa sida soo socota:

● Hagaajinta muuqaalka

Ku dar midabyo gaar ah oo qurux badan

● Beddel dhalaalka

● Kor u qaad iska caabinta kiimikada

● Kordhi iska caabinta xidhashada

● Xaddid saamaynta daxalka

● Iska yaree khilaafka

● Ka saar cilladaha dusha sare

● Nadiifinta qaybaha

● U adeegso jaakad asal ah

● Hagaaji cabbirada

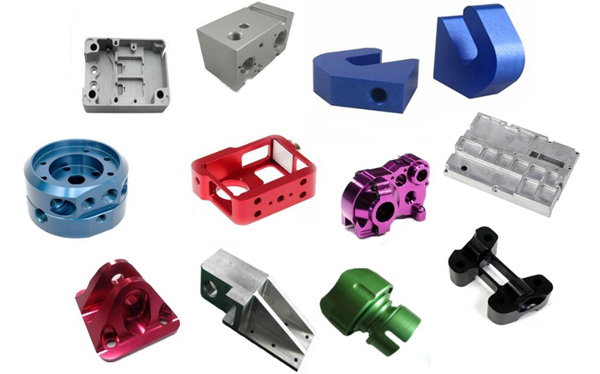

Kachi, Kooxdayada xirfadlayaasha ah ee khabiirada ayaa kugula talin doona daaweynta dusha sare ee ugu habboon iyo farsamooyinka dhamaystirka si loo gaaro natiijooyinkaaga la rabo.Waxaad dooran kartaa dhammaadka ugu fiican ee xoojiya oo ilaaliya muuqaalka qaybaha mashiinka.Nidaamyada daaweynta dusha sare ee jira waxaa ka mid ah sida soo socota:

Anodize

Anodize waa geedi socodka passivation electrolytic kaas oo koraya lakabka oksaydhka dabiiciga ah ee qaybaha aluminium si looga ilaaliyo xirashada iyo daxalka, iyo sidoo kale saamaynta qurxinta.

Qarxinta Usha

Qarxinta warbaahintu waxay isticmaashaa jet la cadaadiyay ee warbaahinta xoqin si ay u mariso matte, dhammays lebis ah oogada qaybaha.

Korantada

Plating Nickel waa hab loo isticmaalo in lagu dhejiyo lakab khafiif ah oo nikkel ah oo lagu dhejiyo qayb bir ah.Dajintan waxaa loo isticmaali karaa daxalka iyo xirashada caabbinta, iyo sidoo kale ujeedooyinka qurxinta.

shaandhaynta

Qaybaha mashiinada CNC ee gaarka ah ayaa gacanta lagu sifeeyay jihooyin badan.Dushu waa siman yihiin oo wax yar bay milicsanayaan.

Chromate

Daawaynta Chromate waxay khusaysaa iskudhis chromium ah oogada birta ah, taasoo siinaysa birta dhamaystir u adkaysata daxalka.Noocan dusha sare ah ayaa sidoo kale siin kara birta muuqaal qurxin, waana saldhig wax ku ool ah oo loogu talagalay noocyo badan oo rinji ah.Ma aha oo kaliya, laakiin sidoo kale waxay u ogolaataa birta inay ilaaliso dhaqdhaqaaqa korantada.

Rinjiyeynta

Rinjiyeyntu waxay ku lug leedahay ku buufinta lakabka rinjiga dusha qaybta.Midabada ayaa la mid noqon kara nambarka midabka Pantone ee doorashada macmiilka, halka dhammayntu ay u dhaxayso matte ilaa dhalaal ilaa macdan.

Black Oxide

Madow oksaydhisku waa daahan beddelaad la mid ah Alodine kaas oo loo isticmaalo birta iyo birta aan lahayn.Waxaa inta badan loo isticmaalaa muuqaalka iyo iska caabbinta daxalka fudud.

calaamadaynta qaybta

Calaamadaynta qaybtu waa hab wax ku ool ah oo lagu daro calaamado ama xarfo gaar ah naqshadahaaga waxaana badanaa loo adeegsadaa qayb ka mid ah calaamadaynta inta lagu jiro wax soo saarka buuxa.

| Shayga | Dhammaystiryada dusha sare ee la heli karo | Shaqada | Dahaarka Muuqaalka | Dhumucda | Heerka | Qalab ku habboon |

| 1 | Nadiifi Anodize | Ka-hortagga oksidation-ka, ka-hortagga-xukunka, qurxin sawirka | Cad, madow, buluug, cagaar, dahab, casaan | 20-30μm | ISO7599, ISO8078, ISO8079 | Aluminium iyo alwaaxdiisa |

| 2 | Anodize adag | Anti-oxidizing, Anti-stacic, waxay kordhisaa caabbinta abrasion iyo adkaanta dusha sare, qurxinta | Madow | 30-40μm | ISO10074, BS/DIN 2536 | Aluminium iyo alwaaxdiisa |

| 3 | Alodine | Kordhi iska caabbinta daxalka, kor u qaad qaabka dusha sare iyo nadiifinta | Cad, aan midab lahayn, huruud ah, bunni, cawl, ama buluug ah | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, heerarka Mil-spec | Biraha kala duwan |

| 4 | Dusha sare ee Chrome/Chrome Daabacaad adag | Iska caabbinta daxalka, kordhinta engegnaanta dusha sare iyo caabbinta naaxinta, Anti=daxalaystay, qurxinta | Dahab, qalin dhalaalaya | 1-1.5μm Adag: 8-12μm | Tilmaamaha SAE-AME-QQ-C-320, Fasalka 2E | Aluminium iyo alwaaxdiisa Bir iyo dawadiisa |

| 5 | Plating Nickel-la'aan | Qurxinta, ka hortagga miridhku, kor u adaygga, iska caabinta daxalka | Iftiin, huruud khafiif ah | 3-5μm | MIL-C-26074, ASTM8733 IYO AMS2404 | Biraha kala duwan, birta iyo aluminium alloy |

| 6 | Darista Zinc | Anti-daxalaystay, qurxinta, kordhiyaan iska caabinta daxalka | Buluug, Cadaan, Casaan, Jaalle, Madow | 8-12μm | ISO/TR 20491, ASTM B695 | Biraha kala duwan |

| 7 | Dahab Dahab ah / Qalin | Mawjada korantada iyo korantada-magnetic, qurxinta | Golder, Silver dhalaalaya | Dahab: 0.8-1.2μm Lacagta: 7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Bir iyo dawadiisa |

| 8 | Black Oxide | Anti-daxalaystay, qurxinta | Madow, madow buluug | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Birta Aan Lahayn, Birta Chromium |

| 9 | Rinjiyeynta /Budada | iska caabin daxalka, qurxinta | Madow ama Ral code kasta ama lambarka Pantone | 2-72μm | Heerarka shirkadda kala duwan | Biraha kala duwan |

| 10 | Gudbinta Biraha Aan-la-aanta lahayn | Anti-daxalaystay, qurxinta | Digniin la'aan | 0.3-0.6μm | ASTM A967, AMS2700&QQ-P-35 | Bir daxal laheyn |

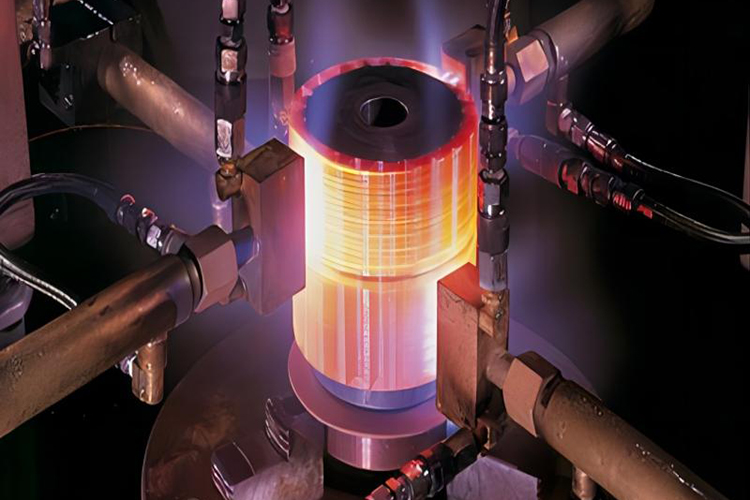

Daawaynta kulaylka

Daawaynta kulaylku waa tallaabo lama huraan u ah mashiinnada saxda ah.Si kastaba ha ahaatee, waxaa jira in ka badan hal hab oo lagu dhammeeyo, iyo doorashadaada daaweynta kulaylka waxay ku xiran tahay alaabta, warshadaha iyo codsiga ugu dambeeya.

Adeegyada Daawaynta Kulaylka

Daawaynta kulaylka birta daawaynta kulaylka waa habka birta lagu kululeeyo ama lagu qaboojiyo jawi si adag loo kontoroolo si loo maareeyo sifooyinkiisa jireed sida mallaalnimadeeda, adkaysigeeda, wax-soo-saarkeeda, adkaanteeda, iyo xooggeeda.Biraha kulaylka lagu daweeyay ayaa lama huraan u ah warshado badan oo ay ku jiraan hawada hawada, baabuurta, kumbuyuutarka, iyo warshadaha qalabka culus.Kuleyl daawaynta qaybaha birta (sida boolal ama brackets engine) waxay abuurtaa qiime iyadoo horumarinaysa la jaanqaadkooda iyo ku dhaqmidooda.

Daawaynta kulaylku waa hannaan saddex tallaabo ah.Marka hore, birta waxaa lagu kululeeyaa heerkulka gaarka ah ee loo baahan yahay si loo keeno isbeddelka la rabo.Marka xigta, heerkulka waa la ilaaliyaa ilaa birta si siman loo kululeeyo.Ilaha kulaylka ayaa markaa la saaraa, taas oo u oggolaanaysa birta inay si buuxda u qaboojiso.

Birtu waa birta lagu daweeyaa kulaylka ugu badan laakiin habkan waxaa lagu sameeyaa walxo kale:

● Aluminium

● Naxaas

● Naxaas

● Birta shubka

● Copper

● Hastelloy

● Inconel

● Nikkel

● Caag

● Birta Aan Lahayn

Doorashooyinka Kala Duwan ee Daawaynta Kulaylka

Adkeynta:Adkeynta waxaa loo sameeyaa si wax looga qabto cilladaha birta, gaar ahaan kuwa saameeya cimriga guud.Waxaa lagu fuliyaa iyadoo la kululeynayo birta oo si degdeg ah loo demiyo marka ay gaarto hantida la rabo.Tani waxay qaboojisaa qaybaha si ay u hesho tayo cusub.

Adkeynta:Adkeynta waxaa loo sameeyaa si wax looga qabto cilladaha birta, gaar ahaan kuwa saameeya cimriga guud.Waxaa lagu fuliyaa iyadoo la kululeynayo birta oo si degdeg ah loo demiyo marka ay gaarto hantida la rabo.Tani waxay qaboojisaa qaybaha si ay u hesho tayo cusub.

Xiritaanka:Inta badan aluminium, naxaasta, birta, qalinka ama naxaasta, annealing waxay ku lug leedahay kuleylinta birta heerkul sare, ku hay halkaas oo u oggolaanaysa inay si tartiib ah u qaboojiso.Tani waxay fududaynaysaa in birahan ay u shaqeeyaan qaab ahaan.Naxaasta, qalinka iyo naxaasta si dhakhso ah ama tartiib ah ayaa loo qaboojin karaa, iyadoo ku xidhan codsiga, laakiin birta had iyo jeer waa inay si tartiib tartiib ah u qaboojiso haddii kale si fiican uma tirtiri doonto.Tan waxa caadiyan la fuliyaa ka hor inta aan la farsamayn si aanay agabku u fashilmin inta lagu jiro wax soo saarka.

Caadiyan:Badanaa loo isticmaalo birta, caadi ka dhigista waxay wanaajisaa mashiinada, ductility iyo xoogga.Birtu waxay kulushahay 150 ilaa 200 darajo ka kulul biraha loo isticmaalo habsocodyada tirtiridda waxaana lagu hayaa halkaas ilaa isbeddelka la rabo uu dhacayo.Nidaamku wuxuu u baahan yahay bir si ay hawadu u qaboojiso si loo abuuro hadhuudh la safeeyey.Tani waxay sidoo kale faa'iido u leedahay ka saarista miraha columnar iyo kala-soocidda dendritic, taas oo wax u dhimi karta tayada marka la tuurayo qayb.

Xanaaqa:Habkan waxaa loo isticmaalaa birta ku salaysan birta, gaar ahaan birta.Alloys-yadani aad bay u adag yihiin, laakiin inta badan aad bay u jajabaan ujeeddooyinkooda.Heerkulku wuxuu birta ku kululeeyaa heerkul wax yar ka hooseeya barta muhiimka ah, sababtoo ah tani waxay yaraynaysaa jajabnaanta iyada oo aan waxyeello u geysan qallafsanaanta.Haddii macaamiil uu rabo caag ka wanaagsan oo leh adayg iyo xoog yar, waxaanu ku kululaynnaa birta heerkul sare.Mararka qaarkood, in kastoo, alaabtu ay u adkaysanayso xanaajinta, waxaana laga yaabaa inay sahlanaato in la soo iibiyo walxo hore u engegay ama in la adkeeyo ka hor inta aan la farsamayn.

Adkeynta Kiis: Haddii aad u baahan tahay dusha adag laakiin udub dhexaadka ka jilicsan, adkaynta kiisku waa betka ugu fiican.Tani waa habka caadiga ah ee biraha leh kaarboon yar, sida birta iyo birta.Habkan, daaweynta kulaylku waxay ku daraysaa kaarboon dusha sare.Waxaad sida caadiga ah dalban doontaa adeeggan ka dib marka qaybo la farsameeyo si aad uga dhigto kuwo sii waaraya.Waxa lagu sameeyaa kulayl sare leh kiimikooyin kale, sababtoo ah taasi waxay yaraynaysaa khatarta ah inay ka dhigto qayb jajaban.

gabowga:Sidoo kale loo yaqaan adkeynta roobka, habkani wuxuu kordhiyaa awoodda wax-soo-saarka biraha jilicsan.Haddii birtu u baahan tahay qallafsanaan dheeraad ah oo ka baxsan qaab-dhismeedkeeda hadda, adkaynta roobabku waxay ku daraysaa wasakh si ay u kordhiso xoogga.Habkani wuxuu badanaa dhacaa ka dib marka la isticmaalo habab kale, oo kaliya waxay kor u qaaddaa heerkulka ilaa heerka dhexe waxayna si dhakhso ah u qaboojisaa walxaha.Haddii farsamayaqaanku go'aamiyo gabowga dabiiciga ah ugu fiican, alaabta waxaa lagu kaydiyaa heerkul qabow ilaa ay ka gaaraan sifooyinka la doonayo.