TŠEBELETSO RONA

KE HOBANE'NG HA U RE KHETHA?

Eketsa Matla a Rōna.Fokotsa Matšoenyeho a Hao.

-

01

01 Boleng bo phahameng le setsebi

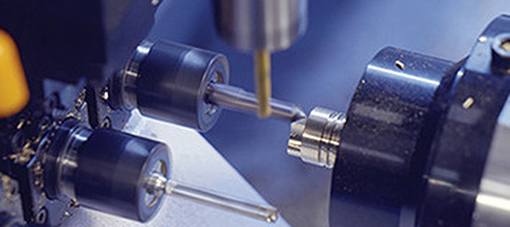

Merero ea hau e tla etsoa ke lienjineri tse hloahloa le tse koetlisitsoeng hantle le balaoli ba boleng ba nang le boiphihlelo ba lilemo tse fetang 10 tsa machining.Sehlopha sa rona sa litsebi se latela maemo a indasteri ka ho sebelisa software ea maemo a holimo, mahlale a morao-rao a CNC, le lisebelisoa tsa ho laola boleng ho etsa likarolo tsa bareki.

-

02

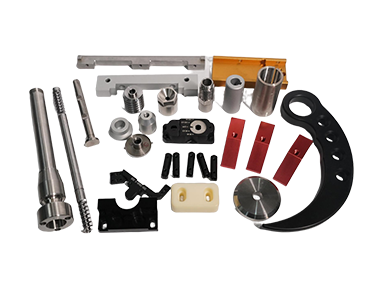

02 Phapang e pharaletseng ea likhetho tsa lisebelisoa

Re fana ka mefuta e mengata ea lintho tse bonahalang, ho akarelletsa le likarolo tsa tšepe (joaloka aluminium, tšepe, tšepe e sa hloekang, carbon steel, koporo, koporo, boronse le motsoako), likarolo tsa polasetiki (joaloka POM, PC, PET, PTFE, PEEK), tse khethehileng. li-alloys (joaloka Kovar, Invar, Inconel, Titanium ), le mefuta e meng ea thepa eo u ka e nahanang.

-

03

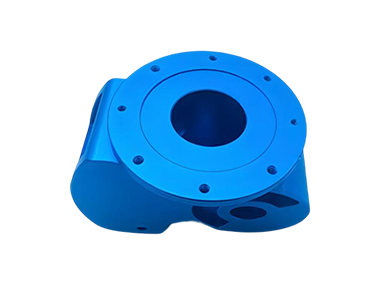

03 Mefuta e mengata ea phekolo ea holim'a metsi le phekolo ea mocheso

Ha re fane feela ka lits'ebeletso tsa machining empa hape le lits'ebeletso tsa ho qeta holimo (joalo ka anodizing, anodizing e thata, black oxide, alodine, chrome plating, electroless nickel plating, joalo-joalo).Bakeng sa likarolo tse hlokang kalafo ea mocheso, re ka e etsa ho latela tlhoko ea hau.

-

04

04 Lits'ebeletso tsa tlhahiso tse bolokang chelete

Litsenyehelo tse tlase tsa tlhahiso ha li bolele boleng bo tlase ba sehlahisoa.Kachi, baenjiniere ba rona ba sekaseka litšoantšo le litlhoko.Ebe u khetha mosebetsi o motle ka ho fetisisa oa ho etsa likarolo tsa hau.Sena se fokotsa nako ea rona ea tlhahiso le litšenyehelo tsa likarolo, ho u fa tšebeletso ea tlhahiso ea nako e sa lefelloeng le e khutšoanyane.

-

05

05 Phano e potlakileng

Kachi e fumaneha Dongguan e tsejoang ka hore ke World-Factory.Re haufi le likou tse kholo tsa likepe 'me re tloaelane le likepe tsa machabeng, tse re lumellang ho tlisa lihlahisoa tsa hau monyako oa hau kapele.

-

06

06 Mechine e tloaelehileng ea CNC

(tse nyane le tse ngata)Re fana ka litšebeletso tsa machining tsa CNC tse nyane le tse phahameng haholo ho bareki ba rona.Ho sa tsotelehe hore na o batla ho khutlisa likarolo tsa khale, leka lisebelisoa tse ncha, kapa o na le litlhoko tse ikhethang, re ka u thusa ka eona.

BONTŠA SEHLAHISO

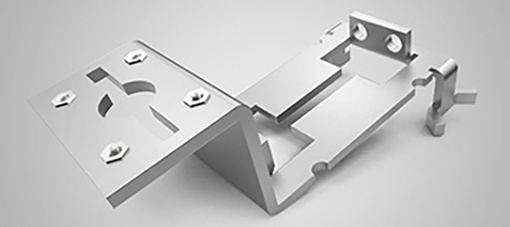

Likarolo tsa Aluminium

Likarolo tsa Aluminium

Bokhoni ba rona ba mochini oa aluminium CNC bo re thusa ho hlahisa mefuta e fapaneng ea likarolo le likopano tse entsoeng ka nepo, ho kenyeletsoa li-castings, die castings, forgings, li-valve tse khethehileng, le lisebelisoa tsa phetisetso le tse feto-fetohang.

Sheba Tse ling

Likarolo tsa Machining tsa Stainless Steel CNC

Likarolo tsa Machining tsa Stainless Steel CNC

Stainless e ka koaheloa ka koporo, zinki, nickel, khauta kapa platinum e fanang ka melemo e meng.Litšobotsi tsena, hammoho le machinability, li etsa hore likarolo tsena e be likhetho tse ntle haholo bakeng sa litaelo tse phahameng haholo.

Sheba Tse ling

Koporo le Koporo

Koporo le Koporo

Brass le koporo ka bobeli ke litšepe tse bohlokoa haholo bakeng sa ho se sebetse ha tsona, ho tšoarella le ho sebetsa ha tsona.

Sheba Tse ling

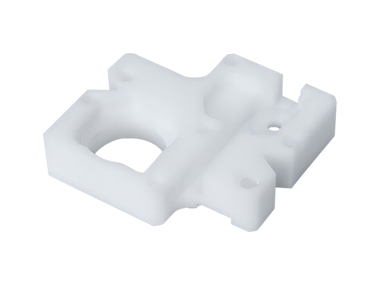

Plastiki & POM

Plastiki & POM

Li-resin tse ngata tsa polasetiki li ka mebala habonolo, li felisa tlhokahalo ea ho penta.Lipolasetiki li fana ka phokotso e kholo ea boima ba 'mele bakeng sa litšenyehelo tse fokotsehileng tsa ho tsamaisa thepa, 'me li-resin tsa thermoplastic hangata li ka sebelisoa hape bakeng sa litšila tse fokotsehileng tsa thepa.

Sheba Tse ling

Likarolo tse Khethehileng tsa Boitsebiso

Likarolo tse Khethehileng tsa Boitsebiso

Sheba Tse ling

Ba bang

Ba bang

Sheba Tse lingBokhoni ba rona

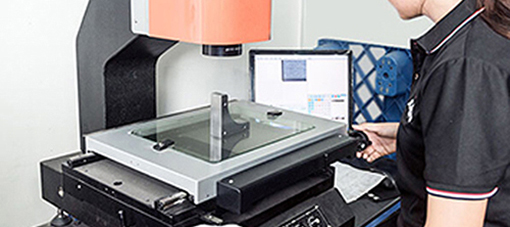

Boleng bo Tla Pele, kachi e netefalitsoe ebile e lumellana le ISO 9001:2015.e re thusitseng ho boloka litšebeletso le lihlahisoa tsa rona ho fihlela tebello ea bareki.

Lihlahisoa tsa boleng ha se feela tsamaiso ea boleng bo botle empa hape le lisebelisoa tse ncha tse tsoetseng pele, sebakeng sa rona sa marang-rang, re ntse re tsoela pele ho tlisa lihlahisoa tse ngata tsa tlhahiso le lisebelisoa tsa tlhahlobo ho tloha kachi qala.mohlala : HASS e tsoang USA, STAR FROM Japan joalo-joalo.

TŠEBELETSO MOTHOE

Khothatso ea rona e kholo ke ts'epo ea bareki ba rona

LITABA

Ho khetha thepa e nepahetseng bakeng sa machining ea CNC ho bohlokoa bakeng sa ho fihlela ts'ebetso e nepahetseng, ho tšoarella, le ho boloka litšenyehelo ...

CNC machining e na le melemo e mengata, kahoo bahlahisi ba e khetha.Le ha mochini oa CNC o sebetsa hantle ebile o sena liphoso ho feta ...

Na CNC Machining ke Ntho e Tšoanang le Khatiso ea 3D? Ha e le hantle, ha li tšoane.Khatiso ea 3D le machining ea CNC li ...

Libaesekele ke mokhoa o tsebahalang oa lipalangoang le boikoetliso, 'me ts'ebetso ea tsona le boleng ba tsona li ipapisitse le ho nepahala le boleng ba karolo ea tsona ...