Ntlafatso ea likoloi

Indasteri ea likoloi e ntse e tsoela pele ka potlako.Ha mekhoa ea indasteri e kang ho khanna ka boithaopo, khokahanyo ea likoloi, le likoloi tse nyalisitsoeng / tsa motlakase li ntse li tsoela pele ho khanna mekhoa e mecha, likarolo tse ling tsa likoloi li fetohile tse boima le tse rarahaneng.Ka thuso ea tlhahiso e potlakileng ea dijithale le maikutlo a boiketsetso a tlhahiso, baqapi le baenjiniere ba ka Fokotsa moralo le kotsi ea litšenyehelo ha ba ntse ba theha ketane ea phepelo e arabelang hantle ho arabela litlhoko tsa mokhanni le bapalami bakeng sa likoloi tse ikhethileng.

Ntlafatso ea kopo ea likarolo tse ncha tsa koloi ea motlakase

Likoloi tsa motlakase le tse ikemetseng ke e 'ngoe ea liindasteri tse atlehileng haholo tse ntseng li hola ka potlako.Ka lebaka leo, lik'hamphani tsa likoloi li ntse li fetola maano a tsona le ho batla likarolo tse ikhethang ho fihlela tlhoko e ntseng e hola.

LIKOPO TSE TLOAELEHANG MOKHOLI

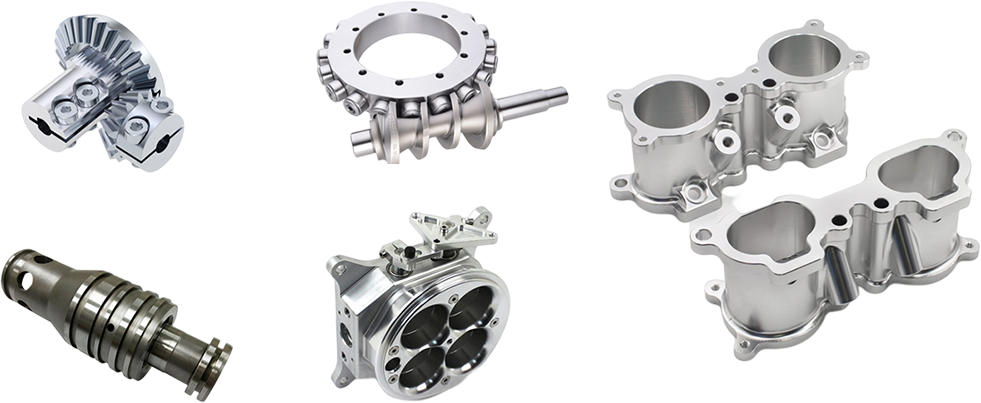

Bokhoni ba rona bo tsoetseng pele ba tlhahiso ea dijithale bo potlakisa tlhahiso ea likarolo tse fapaneng tsa tšepe le polasetiki bakeng sa indasteri ea likoloi.

● Matlo a likoloi

● Sekoahelo sa betri

● Lisebelisoa tsa Dashboard tsa Plastiki

● Ho fokotsa lifensetere

● Lebala la chassis

● Automotive Consumer Electronics

Bokhoni ba ho Etsa Likoloi

Mochini oa CNC

Ho tloha ho tiisetso ea rona ho cnc machining ho fana ka likarolo tse tloaelehileng tse entsoeng ka mochini tse emang teko ea nako ka litšepe tse tšoarellang tsa bongaka tse kenyelletsang titanium, tšepe e sa hloekang, cobalt chrome le lisebelisoa tse ngata tsa koporo.E boetse e u thusa ho fihlela lipheo tsa hau tsa tlhahiso le ho potlakisa nts'etsopele ea lihlahisoa tsa bongaka.

Sheet Metal Fabrication

Ts'ebetso ea tšepe ea pampiri e phetha karolo ea bohlokoa lefapheng la bongaka.Ka ts'ebetso ea tšepe ea lakane, lisebelisoa tse fapaneng tsa bongaka le likarolo li ka hlahisoa, joalo ka matlo, libakete, lithebe, joalo-joalo. Ts'ebetso ea tšepe ea sheet e ka etsa ts'ebetso e nepahetseng ea ho itšeha, ho kobeha, ho otla le ho tjheseletsa ho latela litlhoko tsa moralo ho hlahisa likarolo tse fihlelang litekanyetso tsa sesebelisoa sa bongaka. .

Kalafo ea Bokaholimo

Liphekolo tse fapaneng tsa holim'a metsi li ka ntlafatsa ho hanyetsa ho bola, ho hanyetsa ho roala le botle ba lisebelisoa tsa bongaka.Mekhoa e tloaelehileng ea phekolo ea holim'a metsi e kenyelletsa electroplating, anodizing, spraying, polishing le sandblasting, joalo-joalo Liphekolo tsena li ka ntlafatsa boleng le ho tšepahala ha lihlahisoa, ho finyella litlhoko tsa melao le litekanyetso, le ho ntlafatsa tlhōlisano ea 'maraka oa lihlahisoa.

Bokhoni ba ho Etsa Likoloi

Mochini oa CNC

Ho tloha ho tiisetso ea rona ho cnc machining ho fana ka likarolo tse tloaelehileng tse entsoeng ka mochini tse emang teko ea nako ka litšepe tse tšoarellang tsa bongaka tse kenyelletsang titanium, tšepe e sa hloekang, cobalt chrome le lisebelisoa tse ngata tsa koporo.E boetse e u thusa ho fihlela lipheo tsa hau tsa tlhahiso le ho potlakisa nts'etsopele ea lihlahisoa tsa bongaka.

Sheet Metal Fabrication

Ts'ebetso ea tšepe ea pampiri e phetha karolo ea bohlokoa lefapheng la bongaka.Ka ts'ebetso ea tšepe ea lakane, lisebelisoa tse fapaneng tsa bongaka le likarolo li ka hlahisoa, joalo ka matlo, libakete, lithebe, joalo-joalo. Ts'ebetso ea tšepe ea sheet e ka etsa ts'ebetso e nepahetseng ea ho itšeha, ho kobeha, ho otla le ho tjheseletsa ho latela litlhoko tsa moralo ho hlahisa likarolo tse fihlelang litekanyetso tsa sesebelisoa sa bongaka. .

Kalafo ea Bokaholimo

Liphekolo tse fapaneng tsa holim'a metsi li ka ntlafatsa ho hanyetsa ho bola, ho hanyetsa ho roala le botle ba lisebelisoa tsa bongaka.Mekhoa e tloaelehileng ea phekolo ea holim'a metsi e kenyelletsa electroplating, anodizing, spraying, polishing le sandblasting, joalo-joalo Liphekolo tsena li ka ntlafatsa boleng le ho tšepahala ha lihlahisoa, ho finyella litlhoko tsa melao le litekanyetso, le ho ntlafatsa tlhōlisano ea 'maraka oa lihlahisoa.

Ke lisebelisoa life tse loketseng lisebelisoa tsa likoloi?

Aluminium:

Aluminium alloy e sebelisoa haholo tlhahiso ea likoloi ka lebaka la boima ba eona bo bobebe, matla a phahameng le conductivity e ntle ea mocheso.Mohlala, likarolo tse joalo ka li-block tsa enjine, mabili le chassis hangata li entsoe ka CNC ho tsoa ho lisebelisoa tsa alloy aluminium.

Lisebelisoa tsa carbon fiber:

Li-composites tsa carbon fiber li na le matla a babatsehang le ho satalla ha tsona, ha li ntse li le bobebe ebile li hana ho bola.Ha ho etsoa likoloi, metsoako ea carbon fiber e atisa ho sebelisoa ho etsa likarolo tse kang 'mele, marulelo le ka hare ho trim.

Tšepe:

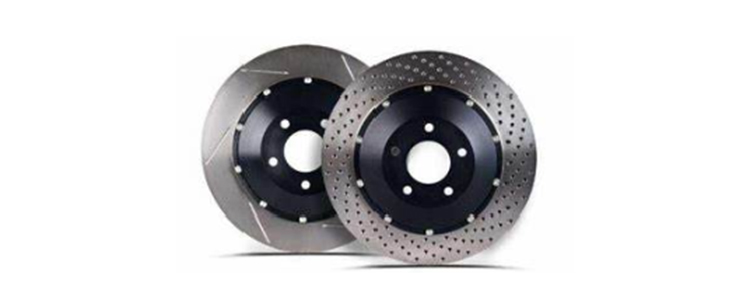

Tšepe e na le matla a phahameng, e hanyetsanang le ho roala, e etsa hore e tšoanelehe bakeng sa likarolo tsa meralo le likarolo tsa likoloi.Ka mohlala, likarolo tsa bohlokoa tse kang liforeimi tsa 'mele, literene tsa likoloi le li-brake systems hangata li entsoe ka CNC ho tloha tšepe.

Plastiki:

Plastiki e na le ho tiea ho hotle, abrasion le khanyetso ea lik'hemik'hale, ha e ntse e le bobebe ebile e theko e tlase.Ha ho etsoa likoloi, lipolasetiki li sebelisoa hangata ha ho etsoa likarolo tsa 'mele oa kantle, mekhabiso ea kahare le lisebelisoa tsa motlakase, har'a tse ling.

Ke lisebelisoa life tse loketseng lisebelisoa tsa likoloi?

Aluminium:

Aluminium alloy e sebelisoa haholo tlhahiso ea likoloi ka lebaka la boima ba eona bo bobebe, matla a phahameng le conductivity e ntle ea mocheso.Mohlala, likarolo tse joalo ka li-block tsa enjine, mabili le chassis hangata li entsoe ka CNC ho tsoa ho lisebelisoa tsa alloy aluminium.

Lisebelisoa tsa carbon fiber:

Li-composites tsa carbon fiber li na le matla a babatsehang le ho satalla ha tsona, ha li ntse li le bobebe ebile li hana ho bola.Ha ho etsoa likoloi, metsoako ea carbon fiber e atisa ho sebelisoa ho etsa likarolo tse kang 'mele, marulelo le ka hare ho trim.

Tšepe:

Tšepe e na le matla a phahameng, e hanyetsanang le ho roala, e etsa hore e tšoanelehe bakeng sa likarolo tsa meralo le likarolo tsa likoloi.Ka mohlala, likarolo tsa bohlokoa tse kang liforeimi tsa 'mele, literene tsa likoloi le li-brake systems hangata li entsoe ka CNC ho tloha tšepe.

Plastiki:

Plastiki e na le ho tiea ho hotle, abrasion le khanyetso ea lik'hemik'hale, ha e ntse e le bobebe ebile e theko e tlase.Ha ho etsoa likoloi, lipolasetiki li sebelisoa hangata ha ho etsoa likarolo tsa 'mele oa kantle, mekhabiso ea kahare le lisebelisoa tsa motlakase, har'a tse ling.

Hlahloba Liindasteri Tse Ling tseo re li Tšehetsang

Re fumane botsebi bo hlokahalang le kutloisiso ea ho fana ka ts'ehetso ho pholletsa le liindasteri tse fapaneng.

Ho kenella ka botebo liindastering tseo re li tšehetsang, tobetsa ka mosa sehokelo se fanoeng.