Ho na le melemo e mengata e fapaneng ea ho sebelisa likarolo tse tloaelehileng tsa CNC indastering ea likoloi.Ka poso ena ea blog, ke tla u tsamaisa ka melemo ena ka botlalo ho u thusa ho utloisisa hore na hobaneng ho khetha le ho reka likarolo tsa CNC tsa moetlo ho le bohlokoa haholo lefatšeng la likoloi.

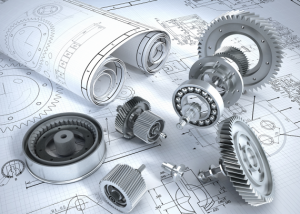

Melemo ea likarolo tse ikhethileng tsa CNC lebaleng la likoloi ke tse latelang:

- ※ Ho nepahala ho phahameng

- ※ Ts'ebetso e phahameng ea tlhahiso

- ※ Ho ikamahanya le maemo ho matla

- ※ Ho boloka litšenyehelo

- ※ Ho tšepahala ho phahameng

Ho nepahala ho phahameng

CNC machining e na le monyetla oa ho fihlela ho nepahala ha maemo a holimo.Sena se bolela hore likarolo li ka etsoa ho fihlela litlhoko tsa moralo ka nepo.Mohlala, ho nepahala ha bophara ba lerako la silinda ea li-block tse ling tsa enjine ea koloi ho ka fihla ho 0.005 mm, e leng se hlokang lisebelisoa tsa mochini oa CNC le lisebelisoa tsa ho lekanya ho fihlela sena.

Taba ea bobeli, machining a CNC a ka fihlela boleng bo holimo bo boreleli le bo ts'oanang.Sena se bolela hore bokaholimo ba karolo bo ke ke ba e-ba le ho se leka-lekane le li-burrs tse ngata, kahoo ho ntlafatsa boleng ba kakaretso ea karolo.Ka mohlala, ho rarahana ha holim'a li-brake discs hangata ho hlokahala hore e be ka har'a Ra 0.4-1.6 microns, 'me CNC machining e ka finyella tlhokahalo ena habonolo.

Ntle le moo, machining a CNC a ka boela a hlokomela tlhahiso ea li-geometri tse rarahaneng.Sena se bolela hore likarolo li ka ba le li-curve tse rarahaneng, li-chamfer, masoba le libopeho tse ling ho fihlela litlhoko tsa moralo oa likarolo tsa koloi.Mohlala, likarolo tse emisitsoeng ho chassis ea koloi hangata li hloka ho ba le libopeho le meaho e rarahaneng ho fana ka botsitso le boiketlo, 'me machining a CNC a ka fihlela litlhoko tsena.

Qetellong, machining a CNC a lumella tlhahiso ea karolo e ka phetoang haholo le e sa fetoheng.Sena se bolela hore karolo e 'ngoe le e' ngoe e lumellana haholo ka boholo le sebōpeho, ho fokotsa litaba nakong ea kopano.Mohlala, litlhoko tsa ho ts'oara boima le boholo ba li-piston lienjineng tsa likoloi hangata li ka har'a ligrama tse 'maloa,' me machining a CNC a ka netefatsa ts'ebetso ena.

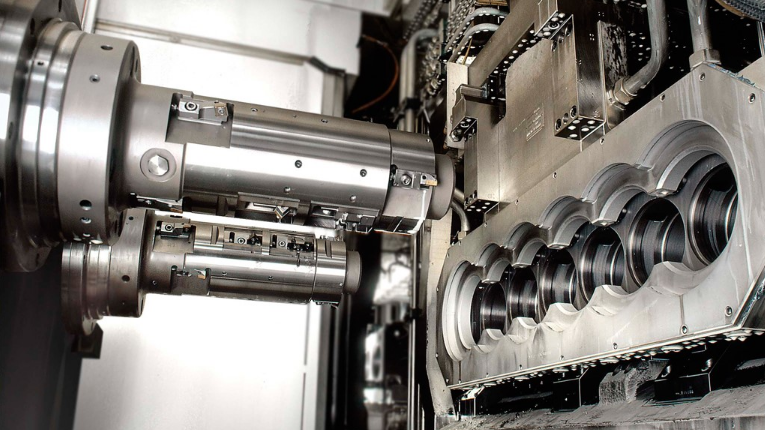

Matla a phahameng a tlhahiso

Tlhahiso e ikemetseng: CNC machining ke ts'ebetso ea boiketsetso e ka laolang lisebelisoa tsa mochini bakeng sa ts'ebetso ka litaelo tse reriloeng esale pele.Ha ho bapisoa le ts'ebetso ea matsoho, ts'ebetso ea CNC e ka fokotsa haholo ho kenella ka letsoho le ho ntlafatsa katleho ea tlhahiso.Ho ea ka lipalo-palo, ho sebelisa ts'ebetso ea CNC ho ka khutsufatsa nako ea tlhahiso ka ho feta 50%.

Mechini ea lebelo le phahameng: Mechini ea CNC e ka sebetsa ka lebelo le holimo, e lumellang likarolo ho etsoa kapele.Ka mohlala, lisebelisoa tse ling tsa CNC li ka sebetsa ka 5,000 revolutions ka motsotso, e leng makhetlo a 'maloa ka potlako ho feta li-lathes tsa setso.Sena se bolela hore likarolo tse ngata li ka hlahisoa ka nako e le 'ngoe, ho ntlafatsa katleho ea tlhahiso.

Tlhahiso ea 'Misa: CNC machining e loketse tlhahiso ea bongata, moo palo e kholo ea likarolo tse ts'oanang e ka hlahisoang ka ho tsamaisa sesebelisoa sa mochini khafetsa.Ha ho bapisoa le ts'ebetso ea matsoho, mochini oa CNC o ka phethela mosebetsi o ts'oanang oa ts'ebetso kapele.Ho ea ka boitsebiso, ho sebelisa CNC ho sebetsa ho ka khutsufatsa nako ea tlhahiso ka ho feta 70%, ho ntlafatsa haholo katleho ea tlhahiso ea bongata.

Ho feto-fetoha ha maemo le ho fetoha ka potlako: CNC machining e ka finyella tlhahiso ea likarolo tse fapaneng ka ho fetola mananeo le lisebelisoa, kahoo e eketsa ho feto-fetoha ha mohala oa tlhahiso.Ha ho bapisoa le mekhoa ea khale ea machining, CNC machining e ka etsa liphetoho tsa ts'ebetso le ho fetoha ha karolo kapele.Ho ea ka lipalo-palo, ho sebelisa CNC machining ho ka khutsufatsa nako ea tokiso ea ts'ebetso ka ho feta 80%.

Ho ikamahanya le maemo ho matla

Ikamahanya le mefuta le litlhoko tse fapaneng: Baetsi ba likoloi hangata ba hloka ho hlahisa likarolo tsa mefuta e mengata e fapaneng le litlhaloso, 'me mochini oa CNC o ka ikamahanya le litlhoko tse fapaneng ka ho fetola mananeo le lisebelisoa.Mohlala, lathe ea CNC e ka etsa mefuta e fapaneng ea likarolo tsa enjene ka ho fetola lisebelisoa le lenaneo ntle le ho nkela sesebelisoa kaofela sa mochini sebaka.Ho feto-fetoha ha maemo ho lumella CNC machining ho ikamahanya le tlhahiso ea mefuta le litlhoko tse fapaneng.

| Car karolo | Lisebelisoa tsa mochini oa CNC |

| likarolo tsa enjene | Piston, hlooho ea silinda |

| Likarolo tsa Brake le mabili | Brake discs, calipers le mabili. |

| Likarolo tse ka hare | Mehato ea mamati, ho fokotsa le likarolo tsa dashboard. |

| ho emisoa le likarolo tsa ho tsamaisa | Laola matsoho, li-knuckles le likarolo tsa ho tsamaisa |

Tse ling tsa likarolo tsa bohlokoa ka ho fetisisa tsa CNC tse entsoeng ka mochine li kenyelletsa likarolo tse kang li-block tsa enjene, li-transmission, le likarolo tse emisitsoeng.Likarolo tsena li hloka mochini o nepahetseng haholo ho netefatsa ts'ebetso e nepahetseng ea motlakase le ts'epahalo, e ka rarolloang ka tlhahiso ea CNC.

Lisebelisoa tsa mochini oa CNC tsa karolo ea koloi

likarolo tsa enjene Piston, hlooho ea silindara

Likarolo tsa Brake le mabili Brake discs, calipers le mabili.

Likarolo tse ka hare tsa mamati, trim le likarolo tsa dashboard.

ho emisoa le likarolo tsa ho tsamaisa Laola matsoho, likonopo le likarolo tsa ho tsamaisa

Ka mohlala:

Tesla

Tesla e sebelisa mochini oa CNC ho hlahisa likarolo tsa koloi ea motlakase, ho kenyeletsoa casings ea betri, matlo a makoloi le likarolo tse emisitsoeng.Ho nepahala le ho nepahala hona ho thusa Tesla ho hlahisa likoloi tsa motlakase tse sebetsang hantle tse nang le nako e telele ea ho khanna le litlhoko tse fokolang tsa tlhokomelo.

BMW

BMW e sebelisa machining a CNC tlhahiso ea enjene ea eona e sebetsang hantle haholo le likarolo tse emisitsoeng.Ho sebelisa theknoloji ea tlhahiso ea CNC ho lumella BMW ho etsa likarolo tse bobebe, tse matla haholo tse thusang ho ntlafatsa ts'ebetso ea mafura a koloi le ho sebetsana le eona.

Ho boloka litšenyehelo

Fokotsa litšila tsa thepa: Machining a CNC a ka fokotsa litšila tsa thepa ka mokhoa o nepahetseng oa ho itšeha le oa machining.Ha ho bapisoa le mekhoa ea setso ea machining, CNC machining e ka laola ka nepo palo ea ho itšeha le botebo ba ts'ebetso, ka hona e fokotsa tlhahiso ea likhechana.Ho ea ka phuputso e 'ngoe, ho sebelisa mochine oa CNC ho ka fokotsa litšila tsa thepa ka hoo e ka bang 30%.

Ntlafatsa katleho ea tlhahiso: Machining a CNC a ka hlokomela lits'ebetso tse ikemetseng, a fokotsa kotsi ea ts'ebetso ea matsoho le liphoso tsa batho.Ho sebetsa ka boiketsetso ho ka ntlafatsa katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso.Ka mohlala, phuputso e 'ngoe e fumane hore ho sebelisa mochine oa CNC ho ka fokotsa nako ea tlhahiso ka ho feta 70% ha ho ntse ho ntlafatsa katleho ea tlhahiso.

Fokotsa litšenyehelo tsa basebetsi: Mechine ea CNC e ka fokotsa tlhoko ea basebetsi ba nang le boiphihlelo le ho fokotsa litšenyehelo tsa basebetsi.Ha ho bapisoa le mekhoa ea khale ea machining, CNC machining e ka fokotsa ho its'etleha ho basebelisi ka lits'ebetso tse reriloeng esale pele le tse ikemetseng.Sena se fokotsa litšenyehelo tsa ho koetlisa le ho hira basebetsi ba nang le litsebo.

Botshepehi bo phahameng

Ntlafatsa ho nepahala ha mochini: mochini oa CNC o ka fihlela mochini o nepahetseng haholo, ka hona oa ntlafatsa boleng le ho nepahala ha likarolo.Ka taolo e nepahetseng ea lenaneo le lits'ebetso tsa mochini o ikemetseng, mochini oa CNC o ka fihlela ho nepahala le ho tsitsa ho holimo.Mochine ona o sebetsang hantle haholo o ntlafatsa polokeho le ts'epahalo ea likarolo tsa koloi le ho netefatsa hore li fihlella litekanyetso tse thata tsa boleng.

Ntlafatsa moralo le ts'ebetso: mochini oa CNC o ka ntlafatsoa ho latela litlhoko tsa moralo le litlhoko tsa ts'ebetso, ka hona, ho ntlafatsa ts'ebetso le ts'epahalo ea likarolo.Ka taolo e nepahetseng ea lenaneo le lits'ebetso tsa mochini o ikemetseng, mochini oa CNC o ka fihlela libopeho le meaho e rarahaneng, ho ntlafatsa ts'ebetso le ts'epahalo ea likarolo.Ka mohlala, baetsi ba likoloi ba bang ba sebelisa mochine oa CNC ho hlahisa likarolo tse rarahaneng tsa enjene, kahoo ba ntlafatsa ts'ebetso ea enjene le ho tšepahala.

Ha indasteri ea likoloi e ntse e tsoela pele ho fetoha le ho amohela mahlale a macha, karolo ea mochini oa CNC tlhahisong ea likoloi tsa sejoale-joale e lebelletsoe ho hola feela.Melemo e mengata ea tlhahiso ea CNC, hammoho le bokhoni ba eona ba ho hlahisa likarolo tsa likoloi tse nang le tšusumetso e matla, e e etsa sesebelisoa sa bohlokoahali ts'ebetsong ea tlhahiso.

Ho akaretsa

likarolo tse ikhethileng tsa CNC li na le melemo e mengata indastering ea tlhahiso ea likoloi.Ba ka fana ka ho itšeha le ho sebetsa ka mokhoa o phahameng, ho etsa bonnete ba hore boholo le sebōpeho sa likarolo li tšoana hantle le tse entsoeng, kahoo li ntlafatsa ts'ebetso le polokeho ea koloi.Likarolo tse ikhethileng tsa CNC le tsona li ka ntlafatsa haholo katleho ea tlhahiso, tsa khutsufatsa potoloho ea tlhahiso ea likoloi, le ho fokotsa monyetla oa phoso ea motho.Ntle le moo, likarolo tse ikhethileng tsa CNC li fa baetsi ba li-automaker monyetla o moholo oa ho sebetsana le libopeho le lisebelisoa tse fapaneng ho fihlela mefuta e fapaneng ea likoloi le litlhoko tsa bareki.Likarolo tse ikhethileng tsa CNC hangata li na le boleng bo holimo le bo ts'eptjoang, li ka sebetsa ka mokhoa o tloaelehileng maemong le maemo a fapaneng a rarahaneng, 'me li na le bophelo bo bolelele ba ts'ebeletso.Leha likarolo tsa CNC tsa tloaelo li ka bitsa chelete e ngata hanyane, li ka tlisa melemo ea nako e telele ka ho fokotsa litšenyehelo tsa tokiso le likarolo tse ncha, ho khutsufatsa nako ea tlhahiso, le ho theola litšenyehelo tsa tlhahiso.Ka hona, likarolo tsa CNC tse hlophisitsoeng li loketse baetsi ba likoloi ho ntlafatsa boleng ba sehlahisoa, katleho ea tlhahiso le ho boloka litšenyehelo

Nako ea poso: Oct-16-2023