Lihlahisoa

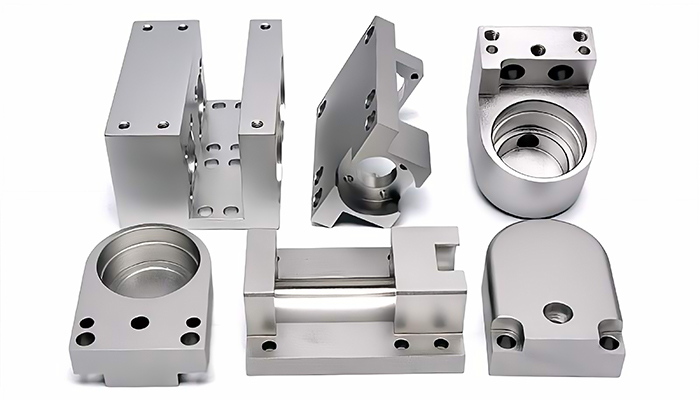

CNC Machining ka Aluminium

CNC Machining Ka Alloy

Litšepe tsa alloy, tse nang le likarolo tse ling tsa alloying hammoho le k'habone, li bonts'a ho thatafala ho matlafalitsoeng, ho tiea, ho hanyetsa mokhathala le ho se mamelle.

Lisebelisoa tsa alloys li sebelisoa hangata lits'ebetsong tsa machining tsa CNC.

Mechine ea CNC e etsa hore ho be le lisebelisoa tsa morao-rao tse sebelisang lisebelisoa tsa tšepe tsa alloy, ho bonts'a thepa e phahameng ea mochine, litekanyo tse nepahetseng le liphello tse ka tšeptjoang.Likhetho tsa ts'ebetso ea machining li kenyelletsa 3-axis le 5-axis CNC milling bakeng sa ho eketseha ha mefuta-futa ea tlhahiso le ho feto-fetoha ha maemo.

Kopo

CNC machining ke mokhoa o ka tšeptjoang oa ho hlahisa likarolo tsa boleng bo phahameng ho tloha thepa ea tšepe le ea polasetiki.E netefatsa thepa e babatsehang ea mechine, litekanyo tse nepahetseng le liphello tse tsitsitseng.Ho feta moo, re boetse re fana ka 3-axis le 5-axis CNC milling ho fihlela litlhoko tse fapaneng tsa tlhahiso.

Melemo

Thepa e phahameng ea mochini oa mochini oa CNC e tiisa ho tšoarella le boleng ba likarolo tseo e li hlahisang.E fana ka ho nepahala ho tsotehang le ho pheta-pheta, ho netefatsa liphetho tse nepahetseng le tse tsitsitseng nakong eohle ea ts'ebetso ea tlhahiso.

Mefokolo

Ha ho bapisoa le khatiso ea 3D, machining a CNC a beha litšitiso tse ngata ho rarahano ea jiometri e ka fihlellehang, e qetellang e fokotsa mefuta e mengata ea menyetla ea moralo e teng.

Theko

$$$$$

Lead time

<matsatsi a 2

Botenya ba Lerako

0.75 limilimithara

Mamello

±0.125mm (±0.005″)

Boholo ba karolo ea boholo

200 x 80 x 100 cm

Li-alloys ke eng

Li-alloys ke lisebelisoa tsa tšepe tse entsoeng ka ho kopanya likarolo tse peli kapa ho feta, bonyane e 'ngoe ea tsona e le tšepe.Motsoako oa likarolo tse fapaneng o fana ka thepa e khethehileng ho motsoako o fapaneng le oa likarolo tsa motho ka mong.

Mefuta ea li-alloys:

Ho na le mefuta e 'maloa ea li-alloys tse thehiloeng ho likarolo tseo li nang le tsona le thepa ea tsona.Mefuta e meng e tloaelehileng e kenyelletsa:

- Tšepe:Tšepe ke motsoako oa tšepe le k'habone, 'me khabone hangata e tloha ho 0.2% ho isa ho 2.1%.E tsebahala ka matla a eona a holimo, ho tšoarella nako e telele, le ho feto-fetoha ha maemo.Tšepe e ka boela ea kopanngoa le likarolo tse ling ho ntlafatsa thepa e khethehileng.

- Ts'epe e sa beng le mabali:Tšepe e sa hloekang ke motsoako oa tšepe, chromium, 'me ka linako tse ling likarolo tse ling tse kang nickel kapa molybdenum.Ha e khone ho bola haholo, e etsa hore e tšoanelehe bakeng sa lisebelisoa moo ho hanyetsanang le mafome le litšila ho hlokahalang.

- Lisebelisoa tsa aluminium:Lisebelisoa tsa aluminium li entsoe ka ho kopanya aluminium le likarolo tse ling tse kang koporo, zinki, magnesium kapa silicon.Li-alloys tsena li fana ka tekanyo e ntle ea matla, thepa e bobebe, le ho hanyetsa kutu.Li sebelisoa haholo liindastering tse kang sefofane, likoloi le kaho.

- Lisebelisoa tsa titanium:Lisebelisoa tsa titanium li entsoe ka ho kopanya titanium le likarolo tse ling tse kang aluminium, vanadium, kapa tšepe.Li tsebahala ka tekanyo ea tsona e phahameng ea boima ba 'mele, khanyetso e ntle ea kutu, le biocompatibility.Li-alloys tsa Titanium li sebelisoa hangata indastering ea lifofane, tsa bongaka le tsa lik'hemik'hale.

Thepa le melemo:

Hangata li-alloys li bontša thepa e ntlafetseng ha e bapisoa le litšepe tse hloekileng.Lintho tsena li ka kenyelletsa matla a eketsehileng, ho thatafala, ho hanyetsa kutu, ho hanyetsa mocheso, le motlakase oa motlakase.Li-alloys le tsona li ka hlophisoa ho latela lits'ebetso tse ikhethileng ka ho lokisa sebopeho le mekhoa ea ts'ebetso.

Lisebelisoa:

Li-alloys li na le mefuta e mengata ea ts'ebeliso ho liindasteri tse fapaneng.Ka mohlala, tšepe e sebelisoa makaleng a kaho, a likoloi le a tlhahiso.Litšepe tse sa hloekang hangata li fumanoa lisebelisoa tsa kichineng, lisebelisoa tsa bongaka le lisebelisoa tsa ho lokisa lik'hemik'hale.Lisebelisoa tsa aluminium li sebelisoa lifofaneng, likoloing le ho paka.Li-alloys tsa Titanium li fumana lits'ebetso sebakeng sa sefofane, li-implants tsa bongaka le lisebelisoa tsa lipapali.

Mekhoa ea tlhahiso:

Li-alloys li ka hlahisoa ka mekhoa e fapaneng, ho kenyelletsa ho lahla, ho forging, extrusion le metallurgy ea phofo.Khetho ea ts'ebetso ea tlhahiso e itšetlehile ka alloy e khethehileng le thepa e lakatsehang.