Lihlahisoa

CNC Machining ka Aluminium

CNC Machining Ka Tšepe e Bonolo

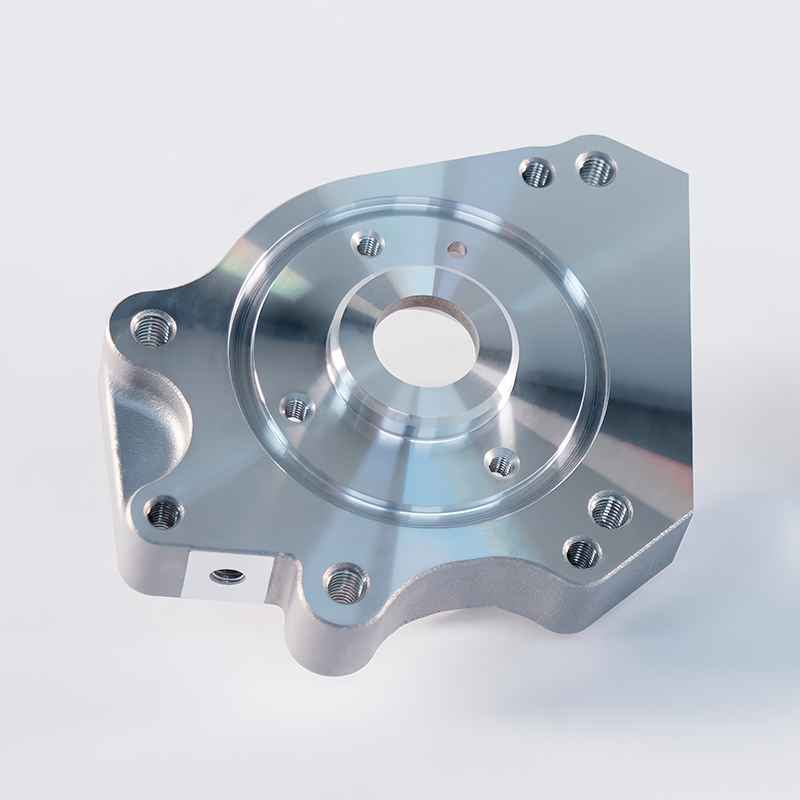

Odara likarolo tse entsoeng ka mochini oa CNC tse entsoeng ka tšepe e bonolo, alloy ea tšepe e theko e tlase e nang le machinability e ntle haholo le ho cheseha, hammoho le ho satalla ho hoholo.

Litšepe tse bonolo le tsona li ka khabisoa ho matlafatsa boima ba eona.

Lisebelisoa tsa tšepe tse bonolo li sebelisoa hangata mekhoeng ea machining ea CNC.

CNC machining e khona ho hlahisa likarolo tsa boemo ba pele ho tsoa lisebelisoa tsa tšepe tse bonolo, tse fanang ka thepa e ntle ea mochini, boholo bo nepahetseng le liphetho tse tšepahalang.Mekhoa ea tlhahiso e ka sebelisa likhetho tsa 3-axis kapa 5-axis CNC ho fihlela sephetho se lakatsehang.

Kopo

Likarolo tsa tšepe le tsa polasetiki tse entsoeng ke mochini oa CNC li na le thepa e ntle ea mochini, e netefatsang ho tšoarella le ho ts'epahala.Ntle le moo, mochini oa CNC o fana ka ho nepahala ho ikhethang ho hlahiseng litekanyo tse nepahetseng tsa likarolo tsena.Ho feta moo, theknoloji e tiisa ho pheta-pheta ho phahameng, ho netefatsa liphetho tse tsitsitseng le tse ka hlahisoang hape.Ho fihlela litlhoko tse fapaneng tsa tlhahiso, likhetho tsa 3-axis le 5-axis CNC lia fumaneha.

Melemo

CNC machining e tsejoa ka thepa ea eona e phahameng ea mochini, eo le eona e netefatsang boleng le ho tšoarella ha likarolo tse hlahisoang.Ho nepahala le ho pheta-pheta ke melemo e 'meli ea bohlokoa ea mokhoa ona oa tlhahiso, kaha o tiisa liphello tse nepahetseng le tse tsitsitseng nakong eohle ea ts'ebetso.

Mefokolo

Ha ho bapisoa le khatiso ea 3D, menyetla ea moralo bakeng sa machining ea CNC e lekantsoe ka lebaka la lithibelo tse thata mabapi le ho rarahana ha geometri.

Theko

$$$$$

Lead time

<matsatsi a 10

Botenya ba Lerako

0.75 limilimithara

Mamello

±0.125mm (±0.005″)

Boholo ba karolo ea boholo

200 x 80 x 100 cm

Lisebelisoa tsa tšepe tse bonolo

Tšepe e bonolo, e tsejoang hape e le low carbon steel kapa plain carbon steel, ke mofuta oa carbon steel o nang le khabone e tlase (hangata e ka tlase ho 0.25%).Ke mofuta o atileng haholo oa tšepe o sebelisoang liindastering tse fapaneng ka lebaka la ho khoneha, ho feto-fetoha ha maemo, le bonolo ba ho etsa masela.

E 'ngoe ea melemo ea bohlokoa ea tšepe e bonolo ke ho cheseha ha eona hantle.E ka chesetsoa habonolo ho sebelisoa mekhoa e fapaneng, joalo ka welding ea arc, welding ea MIG, le welding ea TIG, e etsa hore e lokele ho kopanya likarolo le meaho e fapaneng.

Le hoja tšepe e bonolo e na le matla a tlaase ha e bapisoa le litšepe tse matla haholo, e ntse e bontša matla a lekaneng bakeng sa lisebelisoa tse ngata.E boetse e fana ka ductility e ntle, e e lumellang ho mamella deformation ntle le fracturing.Tšepe e bonolo e ka matlafatsoa le ho feta ka lits'ebetso tse kang ho sebetsa ho batang kapa kalafo ea mocheso.

Leha ho le joalo, tšepe e bonolo e kotsing ea ho bola, haholo-holo libakeng tse nang le mongobo o phahameng kapa ho pepesehela lik'hemik'hale.Ho matlafatsa matla a eona a ho bola, tšepe e bonolo e ka apesoa ka lintho tse sireletsang tse kang pente, galvanizing kapa phofo.