Isicelo

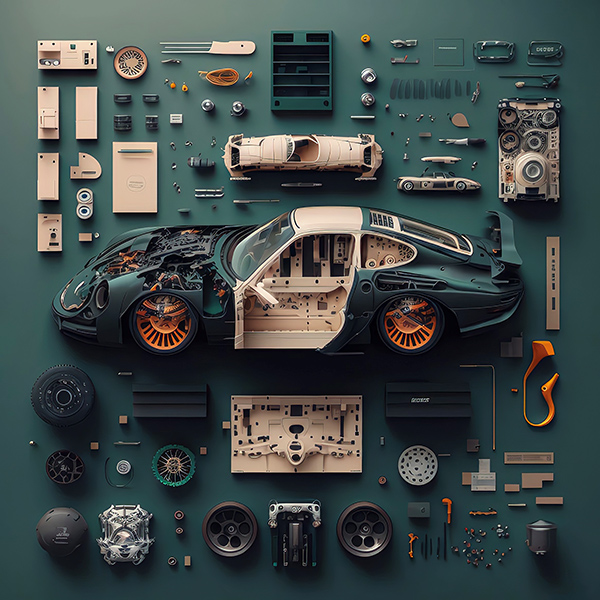

zezinto zetsimbi kwimveliso yasendle

───── Izinto eziqhelekileyo zetsimbi kunye nokusetyenziswa kwazo kwimveliso yeemoto ─────

Metal Materials Bonisa

1. I-alloy ye-Aluminiyam: I-alloy ye-aluminiyam inobunzima, inamandla aphezulu kunye nokuxhathisa okulungileyo kokuhlwa kwaye isoloko isetyenziselwa ukuveliswa kwemizimba yemoto kunye nezakhiwo.Umzekelo, iqokobhe lomzimba, iingcango, ihood, kunye nezinto ze-chassis zihlala zenziwe nge-aluminium alloy ukunciphisa ubunzima besithuthi kunye nokuphucula ukusebenza kakuhle kwamafutha.

2. Insimbi engenasici: insimbi engenasici ine-corrosion resistance, amandla aphezulu, kunye nokumelana nokushisa okuphezulu, okuqhelekileyo kusetyenziswa ekwenzeni iinkqubo zokukhupha iimoto, iinkqubo zokungenisa umoya kunye neenkqubo ze-hydraulic.Ngokomzekelo, amacandelo afana nemibhobho yokukhupha, imibhobho yokungenisa umoya, imibhobho ye-hydraulic, kunye ne-sensors ngokuqhelekileyo zenziwe ngensimbi engenasici ukuphucula ukuqina nokuthembeka.

───── Izixhobo zetsimbi kunye nokusetyenziswa kwazo kwimveliso yerobhothi ─────

Metal Materials Bonisa

1. I-alloys ye-Copper: I-alloys ye-Copper ine-conductivity efanelekileyo yombane kunye ne-thermal kwaye isetyenziswa ngokuqhelekileyo ekwenzeni iinkqubo zombane kunye neenkqubo zokutshatyalaliswa kobushushu kwiirobhothi.Umzekelo, amacandelo eerobhothi anje ngeengcingo, iintambo, iisinki zobushushu, kunye nee-battery contactors zihlala ziveliswa kusetyenziswa iialloyi zobhedu ukubonelela ngokuqhuba kakuhle kombane kunye nokuchithwa kobushushu.

2. I-Aluminiyam i-alloy: I-alloy ye-aluminium enye yezinto eziqhelekileyo zetsimbi ezisetyenziswa kwi-robot yokuvelisa, ezinobunzima, amandla aphezulu, kunye nokumelana nokugqwala okulungileyo.Umzimba, isakhelo, kunye nezakhiwo zeerobhothi zihlala ziveliswa kwi-alloys ye-aluminium ukunciphisa ubunzima obupheleleyo kunye nokuphucula ukuhamba kunye nokuguquguquka kwerobhothi.

───── Izinto eziqhelekileyo zetsimbi kunye nokusetyenziswa kwazo kwimveliso yeedrones ─────

Metal Materials Bonisa

1. Insimbi engenasici: Insimbi engenasici ine-corrosion resistance, amandla aphezulu, kunye nokumelana nokushisa okuphezulu, kwaye isetyenziswa ngokuqhelekileyo ekwenzeni i-sensor, izixhobo ze-elektroniki kunye neenkqubo ze-avionics ze-UAV.Ngokomzekelo, i-sensor yezindlu ze-UAV, izibiyeli zezixhobo ze-elektroniki kunye nezixhumi zentambo, kunye namanye amacandelo ahlala enziwe kusetyenziswa insimbi engenasici ukunika ukhuseleko oluhle kunye nokuthembeka.

2. Ingxubevange ye-Magnesium: i-alloy ye-magnesium inobunzima, amandla aphezulu, kunye neempawu ezintle zemishini, kwaye ilungele ukwenziwa kwee-UAVs ezilula.Ngokomzekelo, amaphiko, i-fuselage shell, kunye nezakhiwo ze-UAV zihlala zenziwe kusetyenziswa i-magnesium alloy ukunciphisa ubunzima obupheleleyo kunye nokuphucula ixesha lokuhamba kunye nomthamo womthwalo.

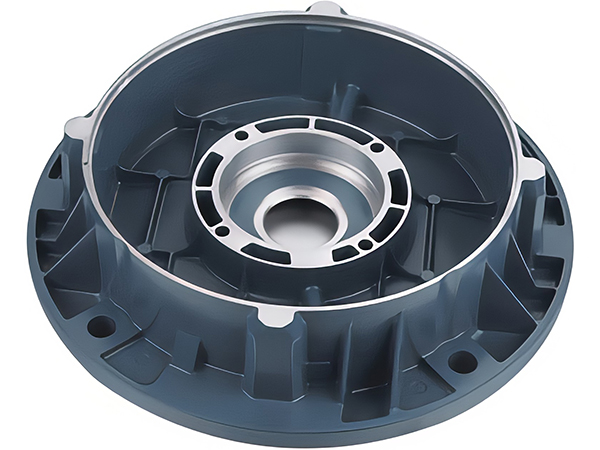

───── Izinto zesinyithi kunye nokusetyenziswa kwazo kwintsimi ye-Oil extraction field ─────

Metal Materials Bonisa

I-1.I-Aluminium Alloy: I-Aluminiyam i-alloy inobunzima obulula, amandla aphezulu kunye ne-conductivity enhle ye-thermal kwaye isetyenziswa ngokuqhelekileyo ekwenzeni izixhobo zesakhiwo kunye ne-radiators kwizixhobo zokukhutshwa kweoli.Ngokomzekelo, iiplatifomu kunye nezibiyeli ezenziwe nge-aluminium alloy zisetyenziselwa ukuxhasa kunye nokulungisa izixhobo, kwaye i-radiator ye-aluminium alloy isetyenziselwa ukutshabalalisa ukushisa kunye nokupholisa phantsi.

I-2.I-Titanium Alloy: Ngamandla aphezulu, ukuxinana okuphantsi kunye nokuchasana kakuhle kwe-corrosion, i-alloys ye-titanium isoloko isetyenziselwa ukuveliswa kwezinto ezichasene ne-corrosion kunye ne-high-temperature components kwi-oil extraction.Ngokomzekelo, iivalve ze-titanium alloy zisetyenziselwa ukulawula ubushushu obuphezulu kunye noxinzelelo oluphezulu, kwaye iibholiti ze-titanium alloy zisetyenziselwa ukudibanisa izixhobo ezibalulekileyo.

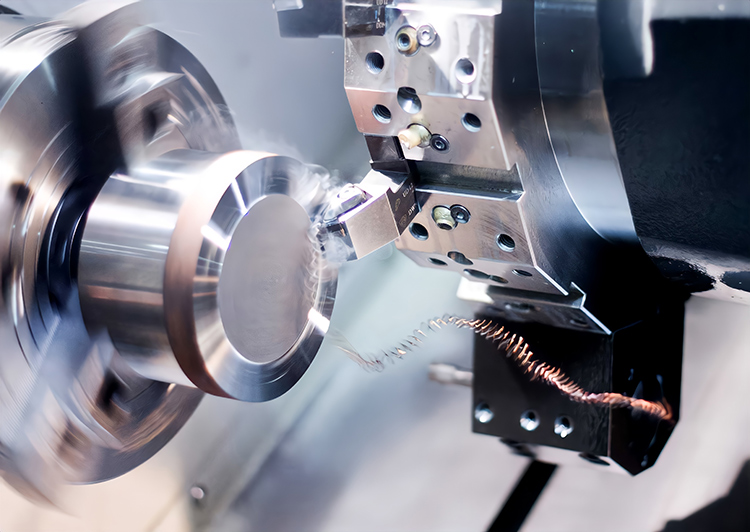

Iinkonzo zeMetal CNC

Amava ngeenkonzo zokusika isinyithi se-CNC ephezulu e-Kachi, enikezela ngekhwalithi engenakulinganiswa kunye namaxesha okutshintsha ngokukhawuleza.sisenza sikwazi ukuzalisekisa ii-odolo ezinomthamo ophantsi wezingxenye zentsimbi ze-CNC kunye nokujongana neeprojekthi zomatshini onzima.Nokuba ufuna iiprototypes okanye ukuveliswa komthamo ophantsi, amandla ethu omatshini wesinyithi we-CNC agubungela uluhlu olubanzi lwesinyithi kunye nokugqitywa komphezulu.Sebenzisana nathi namhlanje ukuze ungene kwikhonkco lethu lokubonelela ngoomatshini bentsimbi ye-CNC.

Metal Machining

Umatshini wesinyithi ubandakanya ukusika isinyithi esikrwada ngokuchanekileyo ukuphumeza imilo okanye into oyifunayo.I-CNC (i-Computerized Numerical Control), eqhutywa yi-software ye-CAD (i-Computer Aided Design), ibonelela ngokuchaneka okungenakulinganiswa ekuveliseni izinto ezintathu-dimensional.Inethiwekhi yethu yoomatshini abanezakhono ikakhulu isebenzisa i-3- kunye ne-5-axis ye-CNC koomatshini abanokusikwa ngokuchanekileyo iimpawu ezintsonkothileyo ngelixa beqinisekisa ukunyamezelana okuqinileyo.Sikwaqhuba iitshekhi ze-intanethi ze-DFM (uYilo lokuVeliswa) ukugcina imigangatho yomgangatho ophezulu.

CNC Metal Fabrication

Ukwenziwa kwentsimbi ye-CNC yinkqubo efanelekileyo yokubumba isinyithi kwiifom ezintsonkothileyo, ezifana nokukrola ibhodi yokusefa eyenziwe ngomthi kodwa ngokuchaneka kwentsimbi, iidrili, kunye neekhompyutha.Ngokusebenzisa oomatshini be-CNC, sinokwenza izakhi zetsimbi ukusuka kwisiqwenga esinye sezinto eziphathekayo, okukhokelela kwimveliso esebenzayo kunye nechanekileyo.

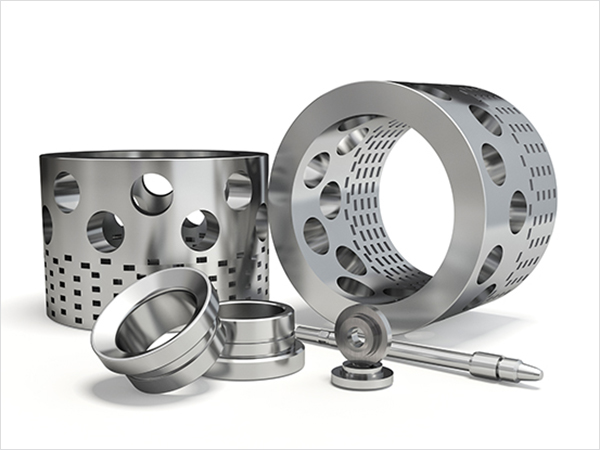

Itheyibhile yokuthelekisa izinto

| Iintsimbi | i-USA | Japhan | Jemani |

| Yenziwe ngentsimbi eshayinayo | 303 | SUS303 | Y1Cr18Ni1.4305 |

| 304 | I-SuS304 | X5CrNi1891.4301 | |

| 316L | SUS316L | X2CrNiMo1812 | |

| 316 | SUS316L | 1.4436 | |

| 202 | SU316 | X12CrNi177 | |

| 410 | I-SuS202 | x1oCr13 | |

| 416 | I-SuS410 | X12CrS13 | |

| - | SUS416 | 1.4021 | |

| 440C | SUS420 | W.1.4125 | |

| 430 | SUS440C | x8Cr17 | |

| 17-7PH | I-SuS430 | 1.4568(1.4504) |

| Iintsimbi | i-USA | Japhan | Jemani |

| Intsimbi yeCarbon | - | SAPH38 | St37-2 |

| 1020 | S20C | CK20 | |

| 1045 | S45C | CK45 | |

| 1213 | SUM22 | 9SMn28 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Ukusika intsimbi | 12L14 | SUM24L | 9SMnpB28 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Intsimbi yentsimbi | 4140 | I-SCM440 | 42CrMo4 |

| P20 | PDS-3 | 1.2311 | |

| D2 | X210Cr12 | SKD11 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Ubhedu | C54400 | C5441 | - |

| C51900 | C5191 | CuSn6 | |

| C17200 | C1720 | Cube2 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Aluminiyam | 6061 | A6061 | AlMg1SiCu |

| 5052 | A5052 | AlMg2.5 | |

| 5083 | A5083 | AlMg4.5Mn | |

| 7075 | A7075 | I-AlZnMgCu1.5 | |

| 7175 | 7075 | I-AlZnMgCu1.5 | |

| 2024 | A2024 | AICuMg2 | |

| 2017 | A2017 | AlCu2.5Mg0.5 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Ubhedu | Т2(99.90) | C1100 | E-Cu57 |

| C21000 | C2100 | CuZn5 | |

| C22000 | C2200 | CuZn10 | |

| C24000 | C2400 | CuZn20 | |

| C26000 | C2600 | Cuzn30 |

| Iintsimbi | i-USA | Japhan | Jemani |

| Ingxubevange | 1045 | S45C | C45 |

| Cr.D | SS400 | S235JR | |

| 1050 | S50C | C50 |