Iimveliso

CNC Machining in Aluminiyam

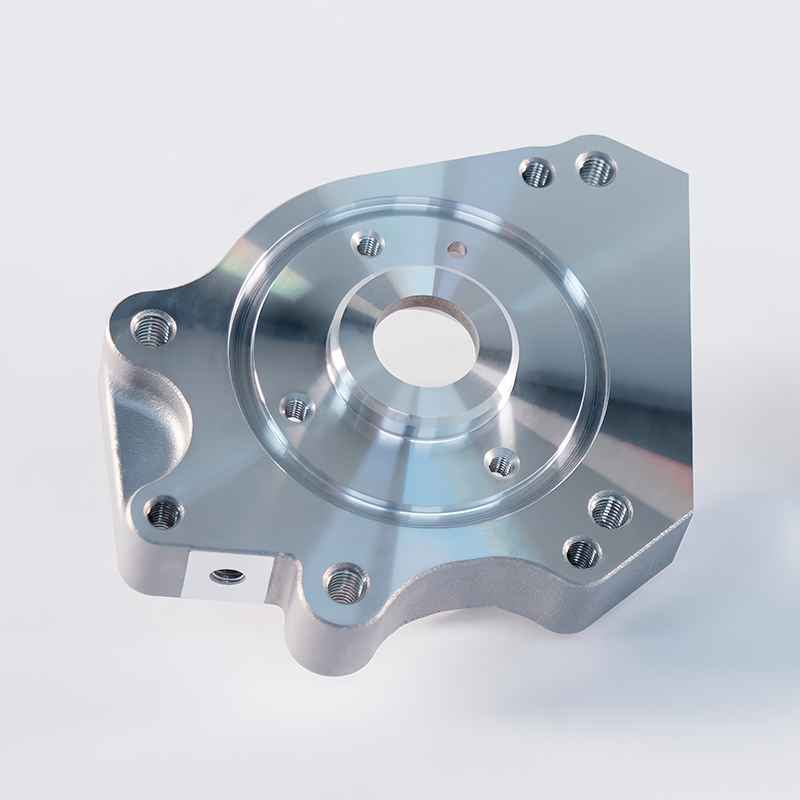

CNC Machining kwi Steel Mild

Umyalelo we-CNC owenziwe ngoomatshini owenziwe ngentsimbi ethambileyo, i-alloy yentsimbi ephantsi ngexabiso eliphantsi kunye nobuchule obugqwesileyo kunye nokuqina, kunye nokuqina okuphezulu.

Intsimbi ethambileyo inokuphinda ifakwe i-carburized ukuqinisa ubulukhuni bayo.

Izinto ezithambileyo zentsimbi zisetyenziswa ngokuqhelekileyo kwiinkqubo zomatshini ze-CNC.

I-CNC machining iyakwazi ukuvelisa amacandelo eklasi yokuqala ukusuka kwizinto ezithambileyo zentsimbi, ukubonelela ngeempawu ezibalaseleyo zoomatshini, imilinganiselo echanekileyo kunye neziphumo ezithembekileyo.Iinkqubo zokuvelisa zingasebenzisa i-3-axis okanye i-5-axis ye-CNC yokusila iinketho zokuphumeza iziphumo ezinqwenelekayo.

Isicelo

Amalungu esinyithi kunye neplastiki enziwe ngumatshini weCNC aneempawu ezibalaseleyo zoomatshini, eziqinisekisa ukuqina kunye nokuthembeka.Ukongeza, umatshini weCNC unikezela ngokuchaneka okukhethekileyo ekuveliseni imilinganiselo echanekileyo yala macandelo.Ngaphaya koko, itekhnoloji iqinisekisa ukuphindaphindwa okuphezulu, iqinisekisa iziphumo ezingaguqukiyo kunye neziphindaphindekayo.Ukuhlangabezana neemfuno ezahlukeneyo zokuvelisa, iinketho ze-3-axis kunye ne-5-axis ye-CNC yokugaya ziyafumaneka.

Iingenelo

I-CNC machining iyaziwa ngeempawu zayo eziphezulu zoomatshini, ezithi ziqinisekise umgangatho kunye nokuqina kwamalungu avelisiweyo.Ukuchaneka kunye nokuphindaphinda zimbini iingenelo eziphambili zale ndlela yokuvelisa, njengoko iqinisekisa iziphumo ezichanekileyo nezingaguqukiyo kuyo yonke inkqubo.

Iingxaki

Xa kuthelekiswa noshicilelo lwe-3D, amathuba oyilo lweCNC machining anqongophele ngenxa yezithintelo ezingqongqo kubunzima bejometri.

Ixabiso

$$$$$

Ixesha lokukhokhela

< 10 iintsuku

Ukutyeba kweendonga

0.75mm

Ukunyamezelana

±0.125mm (±0.005″)

Ubungakanani benxalenye enkulu

200 x 80 x 100 cm

Izinto zentsimbi ezithambileyo

Insimbi ethambileyo, eyaziwa ngokuba yintsimbi ephantsi yekhabhoni okanye i-carbon steel plain, luhlobo lwentsimbi yekhabhoni equlethe ixabiso eliphantsi lekhabhoni (ngokuqhelekileyo lingaphantsi kwe-0.25%).Yeyona ndlela ixhaphakileyo yentsimbi esetyenziswa kumashishini ahlukeneyo ngenxa yokufikeleleka kwayo, ukuguquguquka, kunye nokulula kokwenziwa.

Enye yeenzuzo eziphambili zentsimbi ethambileyo kukuweldability okugqwesileyo.Iyakwazi ukuthungwa ngokulula usebenzisa iindlela ezahlukeneyo, ezifana ne-arc welding, i-MIG welding, kunye ne-TIG ye-welding, eyenza ilungele ukujoyina amacandelo kunye nezakhiwo ezahlukeneyo.

Nangona intsimbi ethambileyo inamandla aphantsi xa ithelekiswa nentsimbi ephezulu, isabonisa amandla okwaneleyo kwizicelo ezininzi.Ikwabonelela nge-ductility elungileyo, eyivumela ukuba imelane ne-deformation ngaphandle kokuqhekeka.Intsimbi ethambileyo inokuqiniswa ngakumbi ngeenkqubo ezifana nokusebenza okubandayo okanye unyango lobushushu.

Nangona kunjalo, intsimbi ethambileyo iyakwazi ukubola, ngakumbi kwiindawo ezinomswakama ophezulu okanye ukuvezwa kweekhemikhali.Ukomeleza ukuxhathisa kwayo ekudlekeni, intsimbi ethambileyo inokugqunywa ngezinto ezikhuselayo ezifana nepeyinti, igalvanizing, okanye umgubo wokugquma.