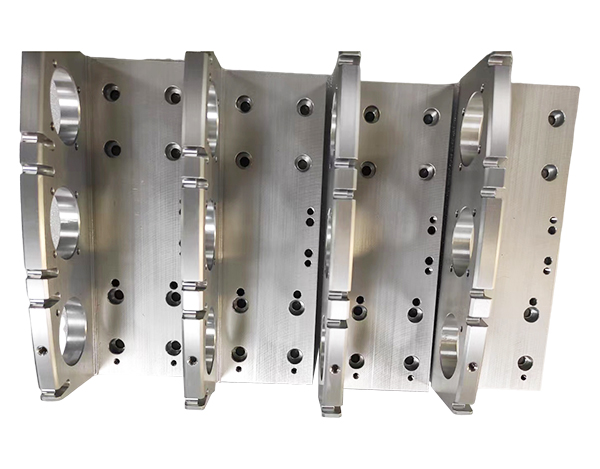

Umphezulu uGqiba kwi-CNC Machining

Ukugqitywa komphezulu yinkqubo enceda ukuchaza kunye nokucokisa ukuthungwa ngokubanzi emva komatshini we-CNC.

EKachi, siqhutywa umgangatho kwaye sikulungele ukwenza ngokwezifiso iinxalenye zosetyenziso olwahlukeneyo.Nokuba ubambelela kunyamezelo oluluqilima kunye nokugqiba okugudileyo okanye ufuna ukonakala okongeziweyo kunye nokumelana nokunxiba, umphezulu wethu ugqibezela ukwenziwa komatshini we-CNC unokuvelisa into oyifunayo.

Yintoni iMachining Surface Finish?

Ukugqitywa komphezulu kubandakanya inkqubo yokuguqula umphezulu wesinyithi ngokuyilwa ngokutsha, ukususa okanye ukongeza, kwaye isetyenziselwa ukulinganisa ukuthungwa komphezulu okuphawulwe ngu:

Lala– Isalathiso sepateni ephambili yomhlaba (idla ngokumiselwa yinkqubo yokuvelisa).

Waviness-Ibhekiselele kwiinkcukacha ezintle zokungafezeki okanye izitenxo ezirhabaxa, ezinje ngeendawo ezijijekileyo okanye eziphambukileyo kwiinkcukacha.

Uburhabaxa boMphezulu– Umlinganiselo wezitenxo zomphezulu ezicandiweyo.Ngokubanzi, uburhabaxa bomphezulu koko oomatshini babhekisa kuko "ukugqiba umphezulu" ngelixa ukusetyenziswa "kokuthungwa komphezulu" kuqhelekile xa kunxibelelene nazo zontathu iimpawu.

Zeziphi iintlobo zezinto ekufuneka ziqwalaselwe xa ukhetha umphezulu womatshini weCNC?

Usetyenziso lwemveliso

Izinto ezahlukeneyo zokusingqongileyo, ezinje ngokungcangcazela, ubushushu, ukufuma, imitha ye-UV, njl., zisetyenziswa kwiindawo ezahlukeneyo zoomatshini be-CNC.Usenokukhetha ngobulumko ukuba uqwalasela ngenyameko ukuba yenzelwe bani kwaye yintoni imveliso leyo.

Ukuqina

Ingaba ufuna imveliso yakho ihlale ixesha elingakanani ngumbuzo ekufuneka uzibuze wona.Ukwenziwa kwemveliso kubandakanya ixesha elide.Impahla ekrwada ibalulekile kule meko, kodwa kufuneka kwakhona uqwalasele ipolishi yomphezulu womatshini.Ukuqina ngumba ekuphuculeni ixabiso lemveliso yakho egqityiweyo.Ke ngoko, kuya kufuneka ukhethe ukugqiba okufanelekileyo.

Imilinganiselo yenxalenye

Kubalulekile ukukhumbula ukuba ukugqitywa komphezulu womatshini kunokuguqula imilinganiselo yenxalenye.Izigqibo ezishinyeneyo ezinjengomgubo wokugquma zinokunyusa ubukhulu bomphezulu wento yesinyithi.

Uncedo lweMetal Surface Finishing Process

Imisebenzi yonyango lomphezulu wesinyithi inokushwankathelwa ngolu hlobo lulandelayo:

● Phucula inkangeleko

● Yongeza imibala ethile emihle

● Guqula ukubengezela

● Ukomeleza ukumelana neekhemikhali

● Yandisa ukuxhathisa ukunxiba

● Ukunciphisa iziphumo zomhlwa

● Nciphisa ukungqubana

● Susa iziphene

● Ukucoca amalungu

● Khonza njengedyasi yokuqala

● Lungisa ubungakanani

E-Kachi, Iqela lethu leengcaphephe zengcali liya kucebisa ngonyango olufanelekileyo lomphezulu kunye neendlela zokugqiba ukufezekisa iziphumo ozifunayo.Ungakhetha ukugqiba okona ukomeleza kunye nokukhusela inkangeleko yamalungu omatshini.Iinkqubo ezikhoyo zonyango lomphezulu zibandakanya oku kungezantsi:

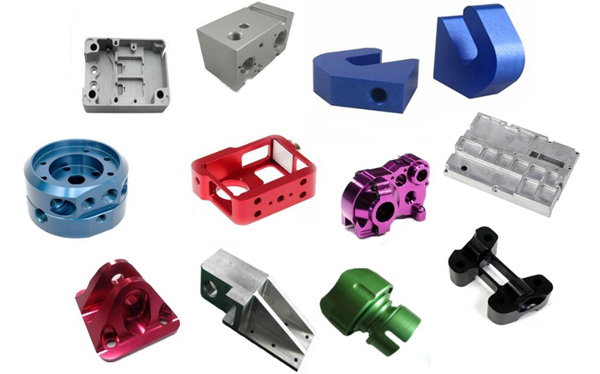

Anodize

I-Anodize yinkqubo ye-electrolytic passivation ekhulisa umaleko we-oxide wendalo kwiindawo ze-aluminiyam ukuze ukhuseleke ekugugeni kunye nokubola, kunye neziphumo zokuthambisa.

Ukuqhushumba kwamaso

Ukuqhushumba kwemidiya kusebenzisa ijethi ecinezelekileyo yemidiya erhabaxa ukufaka i-matte, isiphelo esifanayo kumphezulu wamalungu.

Electroplating

I-Nickel plating yinkqubo esetyenziselwa ukwenza i-electroplate umaleko obhityileyo wenikeli kwindawo yentsimbi.Le plating ingasetyenziselwa ukubola kunye nokumelana nokunxiba, kunye neenjongo zokuhombisa.

Ukugudisa

Amacandelo omatshini e-CNC aqhelekileyo agudiswa ngesandla kwiindlela ezininzi.Umphezulu ugudile kwaye ubonakalisa kancinci.

Chromate

Unyango lwe-chromate lufaka ikhompawundi yechromium kumphezulu wesinyithi, inika isinyithi ukugqiba ukumelana nokudleka.Olu hlobo lokugqitywa komphezulu lunokunika isinyithi imbonakalo yokuhlobisa, kwaye sisiseko esisebenzayo kwiintlobo ezininzi zepeyinti.Akunjalo kuphela, kodwa ivumela isinyithi ukuba igcine umbane wayo.

Ukupeyinta

Ukupeyinta kubandakanya ukutshiza umaleko wepeyinti kumphezulu wenxalenye.Imibala inokudityaniswa nenombolo yePantone yombala okhethwe ngumthengi, ngelixa ukugqiba kuluhlu ukusuka kwimatte ukuya kwiglosi ukuya kwintsimbi.

I-oksidi emnyama

I-oxide emnyama yingubo yokuguqula efana ne-Alodine esetyenziselwa intsimbi kunye nentsimbi.Isetyenziselwa ubukhulu becala ukubonakala kunye nokumelana ne-corrosion encinci.

Ukumakishwa kwenxalenye

Ukumakishwa kwenxalenye yindlela engabizi kakhulu yokongeza iilogo okanye ukubhala ngokwesiko kuyilo lwakho kwaye ihlala isetyenziselwa ukuthegiswa kwenxalenye yesiko ngexesha lemveliso epheleleyo.

| Into | UkuGqiba komphezulu okhoyo | Umsebenzi | Ukwaleka inkangeleko | Ukutyeba | Umgangatho | Umbandela Ofanelekileyo |

| 1 | Cacisa u-Anodize | Ukuthintela i-oxidation, i-anti-friction, ukuhombisa umfanekiso | Icacile, iMnyama, iBlue, eluhlaza, iGolide, iBomvu | 20-30μm | ISO7599, ISO8078, ISO8079 | I-aluminium kunye ne-alloy yayo |

| 2 | Unzima Anodize | I-Anti-oxidizing, i-Anti-static, ukwandisa ukuxhathisa kwe-abrasion kunye nobunzima bomhlaba, ukuhombisa | Mnyama | 30-40μm | ISO10074, BS/DIN 2536 | I-aluminium kunye ne-alloy yayo |

| 3 | Alodine | Ukwandisa ukuxhathisa kwe-corrosion, phucula ubume bomphezulu kunye nokucoceka | Icacile, ayinambala, imbala emthubi, imdaka, ingwevu, okanye ibhlowu | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec imigangatho | Iintlobo ngeentlobo zeMetal |

| 4 | I-Chrome Plating / Ukufakwa kwe-Chrome enzima | Ukuxhathisa umhlwa, kwandisa ubulukhuni bomphezulu kunye nokuxhathisa ukukrazuka, Anti=rusty, ukuhombisa | Igolide, Isilivere eqaqambileyo | 1-1.5μm Nzima:8-12μm | Ukucaciswa kwe-SAE-AME-QQ-C-320, iKlasi 2E | I-aluminium kunye ne-alloy yayo Intsimbi kunye ne-alloy yayo |

| 5 | I-Electroless Nickel Plating | Ukuhlobisa, ukuthintela umhlwa, ukomeleza ubulukhuni, ukuxhathisa umhlwa | Eqaqambileyo, etyheli ekhanyayo | 3-5μm | MIL-C-26074, ASTM8733 KUNYE AMS2404 | Iintlobo ngeentlobo zeMetal, intsimbi kunye neAluminiyam ialloy |

| 6 | Ukufakwa kweZinc | I-Anti-rusty, ukuhlobisa, ukwandisa ukuxhathisa ukubola | Bulu, Mhlophe, Bubomvu, Mthubi, Mnyama | 8-12μm | ISO/TR 20491, ASTM B695 | Iintlobo ezahlukeneyo zeMetal |

| 7 | Igolide / iSilver Plating | Eletric kunye ne-electro-magnetic wave conduction, ukuhombisa | Igolide, iSilivere eqaqambileyo | Golden: 0.8-1.2μm Isilivere: 7-12μm | I-MIL-G-45204, i-ASTM B488, i-AMS 2422 | Intsimbi kunye ne-alloy yayo |

| 8 | I-oksidi emnyama | Ukuchasa umhlwa, ukuhombisa | Mnyama, Bhulowu mnyama | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Intsimbi engatyiwa, iChromium Steel |

| 9 | Ipeyinti yomgubo / ukupeyinta | ukumelana ne-corrosion, ukuhlobisa | Mnyama okanye nayiphi na ikhowudi yeRal okanye inombolo yePantoni | 2-72μm | Umgangatho wenkampani eyahlukileyo | Iintsimbi ezahlukeneyo |

| 10 | Ukugqithiswa kweNsimbi eNgatyiwayo | Ukuchasa umhlwa, ukuhombisa | Akukho zilumkiso | 0.3-0.6μm | I-ASTM A967, AMS2700&QQ-P-35 | Yenziwe ngentsimbi eshayinayo |

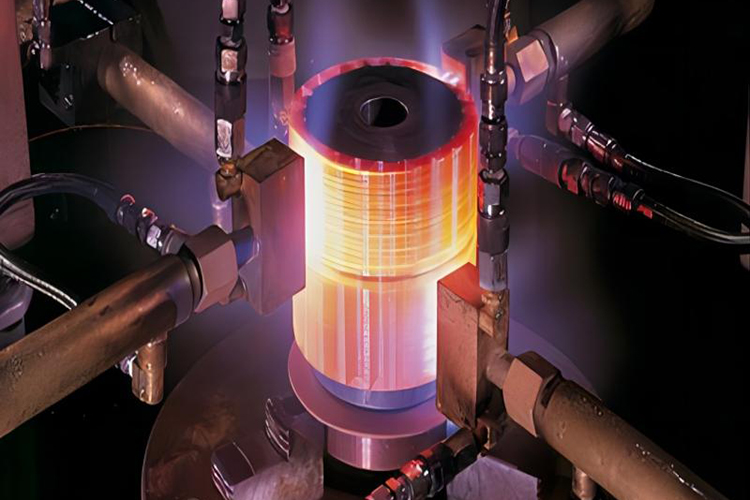

Ukunyanga Ubushushu

Ukunyangwa kobushushu linyathelo elibalulekileyo kumatshini ochanekileyo.Nangona kunjalo, kukho ngaphezu kwendlela enye yokuyifeza, kwaye ukhetho lwakho lonyango lobushushu luxhomekeke kwizinto, ishishini kunye nesicelo sokugqibela.

Iinkonzo Zokunyanga Ubushushu

Ukunyanga i-metalHeat yinkqubo apho intsimbi ifudunyezwa okanye ipholiswe kwindawo elawulwa ngokuqinileyo ukuze ilawule iipropathi zenyama ezifana nokunganyangeki kwayo, ukuqina, ukwenziwa, ukuqina, kunye nokomelela.Iintsimbi eziphathwe ngobushushu ziyimfuneko kumashishini amaninzi aquka i-aerospace, iimoto, ikhompyutha, kunye nemizi-mveliso yezixhobo ezinzima.Ukunyanga iindawo zentsimbi (ezifana nezikrufu okanye izibiyeli ze-injini) kudala ixabiso ngokuphucula ukuguquguquka kwazo kunye nokusebenza kwazo.

Unyango lobushushu yinkqubo enamanyathelo amathathu.Okokuqala, isinyithi sifudunyezwa kwiqondo lokushisa elithile elifunekayo ukuzisa utshintsho olufunekayo.Emva koko, ubushushu bugcinwa de isinyithi sifudunyezwe ngokulinganayo.Umthombo wobushushu uyasuswa, ukuvumela ukuba isinyithi sipholile ngokupheleleyo.

Intsimbi yeyona ntsimbi ixhaphakileyo enyangwa ngobushushu kodwa le nkqubo yenziwa kwezinye izinto:

● IAluminiyam

● Ubhedu

● Ubhedu

● Phosa intsimbi

● Ubhedu

● UHastelloy

● I-incole

● Nickel

● Iplastiki

● Intsimbi engatyiwa

IiNdlela ezahlukeneyo zoNyango loBushushu

Ukuqina:Ukuqina kuyenziwa ukujongana nokusilela kwesinyithi, ngakumbi ezo zichaphazela ukuqina okupheleleyo.Yenziwa ngokufudumeza isinyithi kunye nokucinywa ngokukhawuleza xa ifikelela kwiipropati ezifunwayo.Oku kukhenkceza amasuntswana ukuze kuzuze iimpawu ezintsha.

Ukuqina:Ukuqina kuyenziwa ukujongana nokusilela kwesinyithi, ngakumbi ezo zichaphazela ukuqina okupheleleyo.Yenziwa ngokufudumeza isinyithi kunye nokucinywa ngokukhawuleza xa ifikelela kwiipropati ezifunwayo.Oku kukhenkceza amasuntswana ukuze kuzuze iimpawu ezintsha.

Ukudibanisa:Eyona nto ixhaphakileyo nge-aluminiyam, ubhedu, intsimbi, isilivere okanye ubhedu, i-annealing ibandakanya ukufudumeza intsimbi ukuya kwiqondo lobushushu eliphezulu, ukuyibamba apho kwaye uyivumele ukuba iphole kancinci.Oku kwenza ezi ntsimbi zibe lula ukusebenza ukuze zibe nokumila.Ubhedu, isilivere kunye nobhedu zinokupholiswa ngokukhawuleza okanye ngokucothayo, ngokuxhomekeke kwisicelo, kodwa intsimbi kufuneka ihlale ipholile ngokucothayo okanye ayiyi kuphola ngokufanelekileyo.Oku kuqhele ukwenziwa phambi komatshini ukuze izixhobo zingasileli ngexesha lokwenziwa.

Ukulungelelanisa:Ngokuqhelekileyo isetyenziswe kwintsimbi, i-normalizing iphucula ukunyanzeliswa, i-ductility kunye namandla.I-Steel ifudumeza ukuya kwi-150 ukuya kwi-200 degrees shushu kunezinyithi ezisetyenziswa kwiinkqubo ze-annealing kwaye zigcinwe apho de kwenzeke utshintsho olufunekayo.Inkqubo idinga intsimbi ukuze ipholile emoyeni ukuze yenze iinkozo ezicolisisiweyo ze-ferritic.Oku kuluncedo ekususeni iinkozo ze-columnar kunye nokuhlukaniswa kwe-dendritic, enokuthi idibanise umgangatho ngelixa iphosa inxalenye.

Ukufudumeza:Le nkqubo isetyenziselwa i-alloys-based alloys, ngakumbi intsimbi.Ezi ngxubevange zinzima kakhulu, kodwa zihlala zi-brittle kakhulu kwiinjongo ezijoliswe kuzo.Ubushushu butshisa isinyithi kwiqondo lobushushu elingaphantsi nje kwendawo ebalulekileyo, njengoko oku kuya kunciphisa ukonakala ngaphandle kokubeka esichengeni ubulukhuni.Ukuba umthengi unqwenela iplastiki engcono enobunzima obuncinci kunye namandla, sifudumeza isinyithi kwiqondo lokushisa eliphezulu.Noko ke, maxa wambi, izinto eziphathekayo azikwazi ukuvutha, yaye kusenokuba lula ukuthenga izinto esele ziqinile okanye ziqiniswe ngaphambi kokuba zenziwe.

Ukuqina kwetyala: Ukuba ufuna indawo eqinileyo kodwa ingundoqo ethambileyo, ukuqina kwetyala lolona bhejo lwakho lungcono.Le yinkqubo eqhelekileyo yeentsimbi ezinekhabhoni encinci, njengentsimbi kunye nentsimbi.Kule ndlela, unyango lobushushu longeza i-carbon phezulu.Uya kuthi ngesiqhelo uodole le nkonzo emva kokuba amaqhekeza enziwe ngoomatshini ukuze ubenze bomelele ngakumbi.Yenziwa ngokusebenzisa ukushisa okuphezulu kunye nezinye iikhemikhali, njengoko oko kunciphisa umngcipheko wokwenza inxalenye ye-brittle.

Ukuguga:Ikwaziwa njengokuqiniswa kwemvula, le nkqubo yonyusa amandla esivuno seentsimbi ezithambileyo.Ukuba isinyithi sifuna ukuqina okongeziweyo ngaphaya kwesakhiwo sayo sangoku, ukuqina kwemvula yongeza ukungcola ukwandisa amandla.Le nkqubo ikholisa ukwenzeka emva kokuba ezinye iindlela zisetyenzisiwe, kwaye inyusa kuphela amaqondo obushushu ukuya kumanqanaba aphakathi kwaye ipholise izinto ngokukhawuleza.Ukuba igcisa lithatha isigqibo sokuguga kwendalo kungcono, izinto zigcinwa kumaqondo obushushu apholileyo de zifikelele kwiimpawu ezifunwayo.