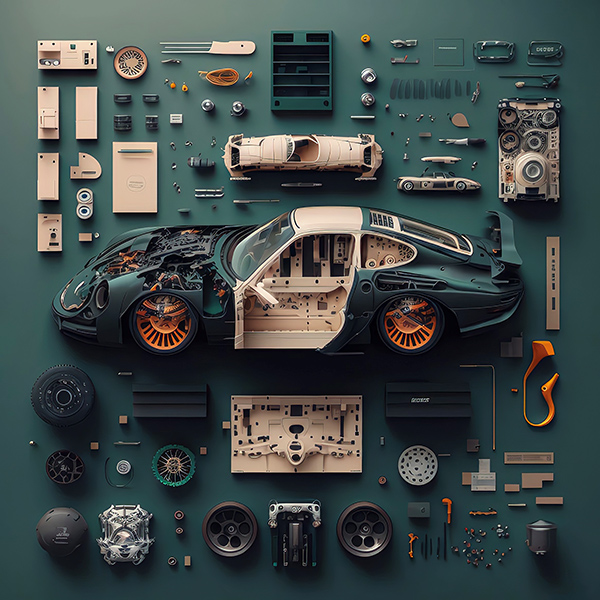

Isicelo

yezinto zensimbi ekukhiqizeni insimu

───── Izinto zensimbi ezivamile kanye nezicelo zazo ekukhiqizeni izimoto ─────

Metal Materials Show

1. Ingxubevange ye-Aluminium: Ingxubevange ye-Aluminium ine-lightweight, inamandla amakhulu futhi imelana nokugqwala okuhle futhi ivame ukusetshenziswa ekwenzeni umzimba wemoto nezingxenye zesakhiwo.Isibonelo, igobolondo lomzimba, izicabha, ihood, kanye nezingxenye ze-chassis ngokuvamile zenziwe nge-aluminium alloy ukuze kwehliswe isisindo semoto futhi kuthuthukiswe ukusebenza kahle kukaphethiloli.

2. Insimbi engagqwali: insimbi engagqwali inokumelana nokugqwala, amandla aphezulu, kanye nokumelana nezinga lokushisa eliphezulu, evame ukusetshenziswa ekwenzeni amasistimu wokukhipha umoya wezimoto, amasistimu okungenisa umoya, nezinhlelo ezisebenza ngamanzi.Isibonelo, izakhi ezinjengamapayipi okukhipha umoya, amapayipi okungenisa umoya, amapayipi amanzi, nezinzwa ngokuvamile zenziwe ngensimbi engagqwali ukuze kuthuthukiswe ukuqina nokuthembeka.

───── Izinto zensimbi kanye nezicelo zazo ekukhiqizeni amarobhothi ─────

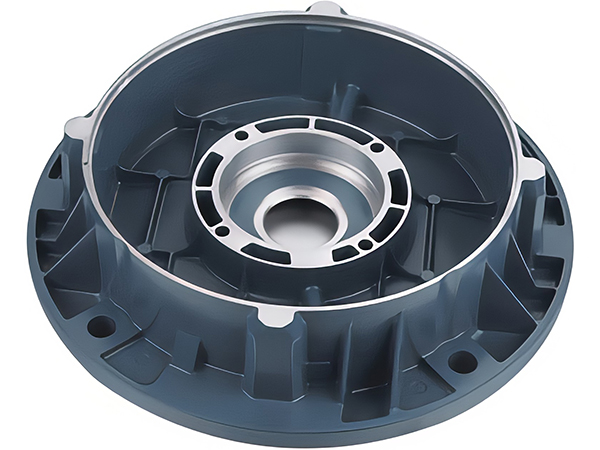

Metal Materials Show

1. Ama-alloys ethusi: Ama-alloys ethusi anokusebenza kahle kukagesi kanye ne-thermal futhi avame ukusetshenziswa ekwenzeni amasistimu kagesi kanye nezinhlelo zokulahla ukushisa kwamarobhothi.Isibonelo, izingxenye zamarobhothi njengezintambo, izintambo, osinki bokushisa, nezixhumi zebhethri ngokuvamile zikhiqizwa kusetshenziswa ama-alloys ethusi ukuze kuhlinzekwe ukuqhutshwa kahle kukagesi kanye nokukhipha ukushisa.

2. Ingxubevange ye-Aluminium: Ingxubevange ye-Aluminium ingenye yezinto ezivamile zensimbi ezisetshenziswa ekwenziweni kwamarobhothi, enesisindo esingasindi, amandla aphezulu, nokungagqwali okuhle.Umzimba, uhlaka, kanye nezingxenye zesakhiwo zamarobhothi ngokuvamile kukhiqizwa kusuka kuma-alloys e-aluminium ukuze kwehliswe isisindo sisonke futhi kuthuthukiswe ukuhamba nokuguquguquka kwerobhothi.

───── Izinto ezisetshenziswayo zensimbi ezivamile kanye nokwenziwa kwazo ekukhiqizeni ama-drones ─────

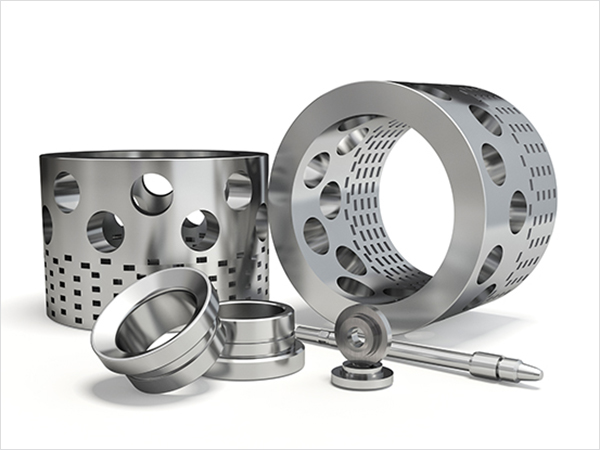

Metal Materials Show

1. Insimbi engagqwali: Insimbi engagqwali inokumelana nokugqwala, amandla aphezulu, nokumelana nezinga lokushisa eliphezulu, futhi ivame ukusetshenziswa ekwenzeni izinzwa, imishini kagesi kanye nezinhlelo ze-avionics zama-UAV.Isibonelo, izindlu zezinzwa ze-UAV, abakaki bezinto zikagesi nezixhumi zekhebula, nezinye izingxenye ngokuvamile zikhiqizwa kusetshenziswa insimbi engagqwali ukunikeza ukuvikeleka okuhle nokwethembeka.

2. Ingxubevange ye-Magnesium: Ingxubevange ye-magnesium ine-lightweight, amandla aphezulu, kanye nezakhiwo ezinhle zemishini, futhi ilungele ukwakhiwa kwama-UAV angasindi.Isibonelo, amaphiko, igobolondo le-fuselage, nezingxenye zesakhiwo se-UAV kuvame ukukhiqizwa kusetshenziswa ingxubevange ye-magnesium ukunciphisa isisindo sisonke futhi kuthuthukiswe isikhathi sendiza namandla okulayisha.

───── Izinto zensimbi kanye nezicelo zabo emkhakheni we-Oil extraction field ─────

Metal Materials Show

I-1.I-Aluminium Alloy: I-aluminium alloy inesisindo esincane, amandla aphezulu kanye ne-conductivity enhle ye-thermal futhi ivame ukusetshenziswa ekwenzeni izingxenye zesakhiwo kanye nama-radiator emishini yokukhipha amafutha.Isibonelo, amapulatifomu namabakaki enziwe nge-aluminium alloy asetshenziselwa ukusekela nokulungisa imishini, futhi ama-radiators e-aluminium alloy asetshenziselwa ukukhipha ukushisa nokupholisa phansi.

I-2.Titanium Alloy: Ngamandla aphezulu, ukuminyana okuphansi kanye nokumelana nokugqwala okuhle, ama-alloys e-titanium avame ukusetshenziswa ekwenzeni izingxenye ezimelana nokugqwala kanye nezingxenye zokushisa okuphezulu emishini yokukhipha uwoyela.Isibonelo, ama-valve e-titanium alloy asetshenziselwa ukulawula izinga lokushisa eliphezulu kanye noketshezi olucindezelayo, futhi ama-titanium alloy bolts asetshenziselwa ukuxhuma imishini ebalulekile.

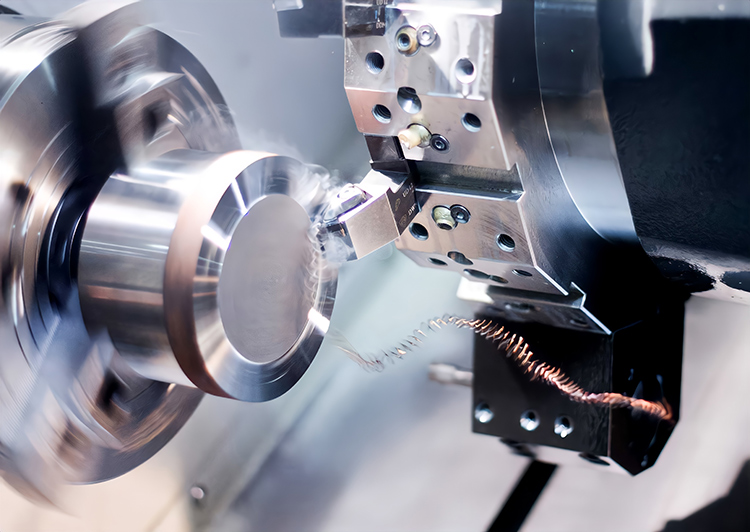

Izinsizakalo ze-Metal CNC

Izwa izinsizakalo zokusika insimbi eziphambili ze-CNC e-Kachi, ezinikeza ikhwalithi engahlulwa nezikhathi zokushintsha ngokushesha.sisenza sikwazi ukufeza ama-oda wevolumu ephansi yezingxenye zensimbi ze-CNC futhi sibhekane namaphrojekthi omshini oyinkimbinkimbi.Kungakhathaliseki ukuthi udinga ama-prototypes noma ukukhiqizwa kwevolumu ephansi, amakhono ethu okwenza insimbi ye-CNC amboza izinhlobonhlobo zezinsimbi kanye nokuqedwa kwendawo.Uzakwethu namuhla ukuze ungene ochungechungeni lwethu olubanzi lwe-CNC metal machining.

Metal Machining

Ukucutshungulwa kwensimbi kuhlanganisa ukusika insimbi eluhlaza ukuze kuzuzwe umumo noma into oyifunayo.Imishini ye-CNC (Computerized Numerical Control), eqhutshwa isofthiwe ye-CAD (Computer Aided Design), inikeza ukunemba okungenakuqhathaniswa ekukhiqizeni izinto ezinezinhlangothi ezintathu.Inethiwekhi yethu yochwepheshe bemishini abanekhono isebenzisa kakhulu imishini ye-CNC engu-3- kanye ne-5-axis engakwazi ukusika ngokunembile izici eziyinkimbinkimbi ngenkathi iqinisekisa ukubekezelelana okuqinile.Siphinde senze amasheke ku-inthanethi e-DFM (Design for Manufacturability) ukuze sigcine amazinga aphezulu ekhwalithi.

I-CNC Metal Fabrication

Ukwenziwa kwensimbi ye-CNC kuyinqubo ekahle yokubumba insimbi ibe amafomu ayinkimbinkimbi, afana nokubaza ibhodi lokuntweza ngokhuni kodwa ngokunemba kwensimbi, izimbobo, namakhompyutha.Ngokusebenzisa imishini ye-CNC, singakwazi ukwenza izingxenye zensimbi kusuka ocezu olulodwa lwempahla, okuholela ekukhiqizeni okuphumelelayo nokunembayo.

Ithebula Lokuqhathanisa Okubalulekile

| Izinsimbi | USA | Japan | EJalimane |

| Insimbi engagqwali | 303 | I-SUS303 | Y1Cr18Ni1.4305 |

| 304 | I-SuS304 | X5CrNi1891.4301 | |

| 316L | I-SUS316L | I-X2CrNiMo1812 | |

| 316 | I-SUS316L | 1.4436 | |

| 202 | I-SU316 | I-X12CrNi177 | |

| 410 | I-SuS202 | x1oCr13 | |

| 416 | I-SuS410 | I-X12CrS13 | |

| - | I-SUS416 | 1.4021 | |

| 440C | I-SUS420 | W.1.4125 | |

| 430 | I-SUS440C | x8Cr17 | |

| 17-7PH | I-SuS430 | 1.4568(1.4504) |

| Izinsimbi | USA | Japan | EJalimane |

| Insimbi Yekhabhoni | - | SAPH38 | St37-2 |

| 1020 | I-S20C | CK20 | |

| 1045 | I-S45C | CK45 | |

| 1213 | I-SUM22 | 9SMn28 |

| Izinsimbi | USA | Japan | EJalimane |

| Insimbi yokusika | 12L14 | I-SUM24L | 9SMnpB28 |

| Izinsimbi | USA | Japan | EJalimane |

| I-alloy Steel | 4140 | I-SCM440 | 42CrMo4 |

| P20 | I-PDS-3 | 1.2311 | |

| D2 | I-X210Cr12 | SKD11 |

| Izinsimbi | USA | Japan | EJalimane |

| Ibhulonzi | C54400 | C5441 | - |

| C51900 | C5191 | CuSn6 | |

| C17200 | C1720 | Cube2 |

| Izinsimbi | USA | Japan | EJalimane |

| I-Aluminium | 6061 | A6061 | I-AlMg1SiCu |

| 5052 | A5052 | I-AlMg2.5 | |

| 5083 | A5083 | I-AlMg4.5Mn | |

| 7075 | A7075 | I-AlZnMgCu1.5 | |

| 7175 | 7075 | I-AlZnMgCu1.5 | |

| 2024 | A2024 | AICuMg2 | |

| 2017 | A2017 | I-AlCu2.5Mg0.5 |

| Izinsimbi | USA | Japan | EJalimane |

| Ithusi | Т2(99.90) | C1100 | E-Cu57 |

| C21000 | C2100 | kuZn5 | |

| C22000 | C2200 | KuZn10 | |

| C24000 | C2400 | kuZn20 | |

| C26000 | C2600 | Cuzn30 |

| Izinsimbi | USA | Japan | EJalimane |

| Ama-alloys | 1045 | I-S45C | C45 |

| Cr.D | I-SS400 | I-S235JR | |

| 1050 | I-S50C | C50 |