Ukusetshenziswa Kwezinto Zepulasitiki

Ekwenziweni Kwezinkundla

01

Izinto zePlastiki kanye nezicelo zazo kuukukhiqiza izimoto

● I-Polypropylene (PP): I-Polypropylene iyinto evamile yepulasitiki enesisindo esincane, ukumelana namakhemikhali kanye nezindleko eziphansi.Emkhakheni wezimoto, i-polypropylene ivame ukusetshenziswa ekwenzeni izingxenye zangaphakathi zezimoto, amabhokisi okugcina kanye nama-bumpers, njll.

● I-Polycarbonate (i-PC): I-Polycarbonate inezici zamandla aphezulu, ukumelana nomthelela nokungafihli kahle.Emkhakheni wezimoto, i-polycarbonate ivame ukusetshenziswa ekwenzeni izibani zezibani zezimoto, izindlu zesibuko namaphaneli wezinsimbi, njll.

02

Izinto zePlastiki kanye nezicelo zazo kuukukhiqizwa kwamarobhothi

● I-Polypropylene (PP): I-Polypropylene iyinto evamile yepulasitiki engasindi, imelana namakhemikhali futhi inezindleko eziphansi zezingxenye zamarobhothi nezixhumi.Isibonelo, izingxenye zerobhothi, abakaki nezixhumi zivame ukufakwa ngomshini we-CNC kusuka ku-polypropylene.

● I-Polystyrene (PS): I-Polystyrene iyimpahla yepulasitiki engasindi, eqinile futhi eshibhile efaneleka izingxenye zesakhiwo nezivikelayo zamarobhothi.Isibonelo, amafreyimu, izisekelo, namakhava amarobhothi kuvame ukwenziwa nge-polystyrene.

03

Izinto zePlastiki kanye nezicelo zazo kuUkukhiqizwa kwezokwelapha

● I-ABS (I-Acrylonitrile Butadiene Styrene): I-ABS iyimpahla yepulasitiki eguquguqukayo eminingi futhi imelana nomthelela evame ukusetshenziswa ekukhiqizeni idivayisi yezokwelapha.Ivamise ukusetshenziselwa ama-casings, izindlu, kanye nezingxenye zesakhiwo zemishini yezokwelapha njengemishini yokuthwebula izithombe, amasistimu okuqapha, namathuluzi aselabhorethri.

● I-Polyetheretherketone (PEEK): I-PEEK i-thermoplastic material esebenza kahle kakhulu eyaziwa ngezici zayo ezinhle kakhulu zemishini, ukumelana namakhemikhali, kanye nokuvumelana kwe-biocompatibility.Ivamise ukusetshenziswa ekukhiqizeni amathuluzi ezokwelapha afakelwayo, amathuluzi okuhlinza, kanye nezingxenye ezidinga amandla aphezulu kanye nokumelana nezinqubo zokuvala inzalo.

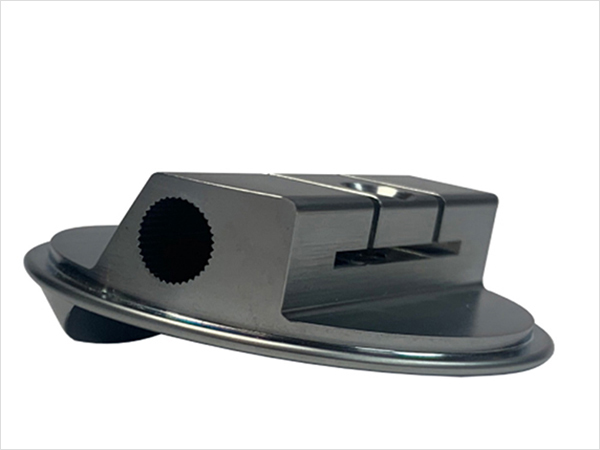

Isingeniso sePlastiki Machining

Izingxenye zomshini wepulasitiki ziyindlela engasindi futhi engabizi kakhulu kunezingxenye zensimbi.Kulula ukuwenza ngomshini futhi anikeze ukuhambisana nohlu olubanzi lwamapulasitiki.I-CNC machining iyinketho ethandwayo yonjiniyela namaqembu emikhiqizo ngenxa yokuguquguquka kwayo.Izinhlobo ezahlukene zamapulasitiki zinamandla azo kanye nobuthakathaka bazo bezinhlelo zokusebenza zemishini ye-CNC.

Izinsizakalo Zomshini Wepulasitiki

Inkampani yethu inikezela ngezinsizakalo zemishini yepulasitiki ye-CNC yesimanje ngokugxila kwikhwalithi engaguquki kanye nezikhathi zokushintsha ngokushesha.Ngenqwaba yemishini yokugaya neyokuguqula, sinamandla okuphatha ama-oda anoma yimuphi usayizi, kusukela kuma-prototypes amancane kuya ekugijimeni kokukhiqiza okuyinkimbinkimbi.Inethiwekhi yethu ebanzi yabakhiqizi isenza sikwazi ukusebenza ngamapulasitiki anhlobonhlobo futhi sinikeze izinketho ezahlukahlukene zokuqeda ngaphezulu.Sizinikezele ekuhlangabezaneni nezidingo zamakhasimende ethu kanye nokuhlinzeka ngezixazululo ezingabizi kakhulu.

Izinzuzo CNC Plastic Machining

I-CNC plastic machining iyinqubo ekhiphayo evumela ukwakhiwa kwezingxenye zepulasitiki eziyinkimbinkimbi.Imishini yethu ye-CNC eyinkimbinkimbi engu-3-, 4-, kanye ne-5-axis ingakhiqiza izingxenye zekhwalithi ephezulu ezinamajiyometri ayinkimbinkimbi.Uma kuqhathaniswa nokuphrinta kwe-3D noma ukubunjwa komjovo, ukwenziwa kwemishini ye-CNC kunikeza ukubekezelelana okuqinile nokukhethwa okubanzi kwezinto ze-polymer.Ibiza kakhulu ekukhiqizeni umthamo ophansi.Ngokusebenzisa uchungechunge lwethu olubanzi lwe-CNC machining machining chain, singaletha izixazululo ezinokwethenjelwa nezisebenzayo zezidingo zakho zokwenza imishini yepulasitiki.

Ithebula Lokuqhathanisa Izinto

| Ipulasitiki | Umbala | Iphoyinti lokuncibilika | Ukuminyana | Isici |

| I-PEEK | Mnyama | 150 ℃ | 1.51 | 1.Ukuqina okuhle kanye nokumelana nomthelela |

| 2.Amandla amahle nobulukhuni, kulula ukulola ummese | ||||

| 3.Ukumelana ne-uv okuhle kakhulu |

| Ipulasitiki | Umbala | Iphoyinti lokuncibilika | Ukuminyana | Isici |

| I-POM | Okumnyama Nokumhlophe | 160 ℃ | 1.41 | 1.Ukumelana nokugqwala okuphezulu kwe-solvent |

| 2.High tensile ukumelana | ||||

| 3.Ukufakwa kahle kukagesi | ||||

| 4.Ukushelela okuhle nokumelana nokuhuzuka |

| Ipulasitiki | Umbala | Iphoyinti lokuncibilika | Ukuminyana | Isici |

| PA | I-Creamy White | 220℃ | 1.14 | 1.I-thermal deformation |

| I-2.Ukushelela okuhle kanye nokuzinza kwamakhemikhali aphezulu | ||||

| 3.Ukuhwamuka okuphezulub |

| Ipulasitiki | Umbala | Iphoyinti lokuncibilika | Ukuminyana | Isici |

| PC | Okusobala, Okunsundu Okumnyama | 150 ℃ | 1.2 | 1.Ukungaguquguquki ukumelana nokushisa |

| 2.Ukufakwa kahle kukagesi | ||||

| 3.Ukumuncwa kwamanzi aphansi, ukuzicisha | ||||

| 4.Ukuqina komthelela ophezulu |

| Ipulasitiki | Umbala | Iphoyinti lokuncibilika | Ukuminyana | Isici |

| PU | Inhlaka | 260℃ | 1.24 | Ukunwebeka okuhle nokuqina, kulungele ukwenza i-elastic gasket |